I have a build thread in the DIY section as many may know but I thought I would redo this build as an article of sorts. This way I can explain the build minus the unorganized chit chat that comes about in any build thread. Also, this write up will contain what I actually did and not any plans I may have strayed from.

First up, a final design picture and the tank as blue prints for anyone interested.

Above is how I made use of 4 sheets without the need for extra lumber for framing.

These measurements are for a 2700mm x 1200mm x 32mm sheet. If your sheets are thinner or thicker, the measurements will inevitably change. External dimension are 2700mm x 1200mm x 1032mm. That equates to 885 gallon but for the sake of simplicity, I call it an 800g as this is what it actually holds going by internal measurements.

The materials required for this build are as such.

Float glass - 2400mm x 850mm x 19mm supplied by http://www.aquariumsrus.com.au

4 Ply sheets - 2700mm x 1200mm x 32mm

Roofing screws

Builders bog

30m x 1m x 300gsm woven roving cloth

18L Boat Cote Epoxy supplied by http://boatcraft.com.au

Black epoxy pigment

4L Acetone for clean up

8 tubes of Silicone

2 clear polycarbonate roofing sheets - 2400mm x 1200mm

2 pvc pipes 3000mm x 25mm for lid hold down only

36 Besser blocks for stand

Sand paper, brushes and general work tools etc.

There were two reasons I opted to use such thick sheets. The first and major reason was to eliminate external bracing altogether. I wanted a somewhat clean appeal to the outside of the tank as well as inside. The second was to help insulate the tank, high on my list of priorities as this build was always intended to be outside. Under cover but still subject to the ambient air temps outside.

With my design in hand, it was time to start ripping these sheets up. You can see above the 98mm rips to the side. When ripping plywood I use a second sheet as a guide. Use a couple of nails to hold it in place but be sure to leave them proud for easy removal once your cut is done.

With the long 98mm rips done it was time to cut out the window. First job was to mark it out, double check it and then drill out the corners with a 45mm OD hole saw. I wanted a nice round corner here not so much for looks but to make it easier to fiberglass at a later date.

With the power saw, I cut out the window freehand and cut the last little bit in the corners with a hand saw. Now with the inside of the window out, I went back to using a sheet as a guide to cut it into the remaining braces.

The main sides went together fairly fast. My son was a big help in this build. I think he enjoyed it immensely. Construction of anything can make for great father/son bonding sessions.

Here is the bottom plate completely screwed off. All screws are counter sunk and pre drilled. Time consuming but a must.

This picture shows the top cross braces well. It also shows the infill pieces between them. I left a recess for the lids to sit in as I wanted them to sit flush with the top of the tank.

All the internal corner braces are in and it is now completely screwed off.

Time to fill all the screws and round off all corners both internal and external. I just used a builders bog for this. Bog is not the best choice for use near water but if water gets to it, it will also get to the ply which means I have a serious problem anyway making it a mute point.

Getting the corners filleted out and rounded off aids in the fiberglassing process later so plenty of time was spent in this part of the preparation.

Fiberglass? I chose this route as I am comfortable working with this medium and it will allow me to construct without the need for external framing. It has exceptional strength, durability and impact resistant properties and applied correctly will last many, many years.

Resin? I believe that if a product is designed specifically for timber boat building, it will be perfect for a plywood aquarium so Bote Cote Epoxy was the choice for this build. On par with West Systems but I find it better in a couple of ways. I would say equal in quality but easier in terms of use. It has a simple 2:1 mix ratio and is a little thicker in viscosity. The main thing I like with Bote Cote is its Hardeners. They are free of the side reaction known as Amine Blush. For those that don't know what that is, it is a residue that forms on the surface of many epoxy resins when they are used in colder or damp conditions. It is a real pain to remove usually having to be scrubbed off with solvents or an ammonia based cleaner before you can continue with sanding, let alone applying the next coats. Bote Cote being free of this means just a simple sand in between coats for correct adhesion is sufficient.

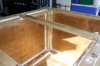

You can see from the pictures above that the resin is already black. I used a pigment to colour the resin as epoxy resins don't have gel coats for a top coat like polyester/vinyl ester resins.

Fibre glassing method? First thing I do is to have all my cloth cut up and ready for all the areas to be glassed. I also make sure the epoxy resin both part A & B are pre warmed to make it easier to work with. I usually mix up about the same amount of resin in weight as the cloth I am using, maybe a little more. e.g. If your cloth is 300gsm (grams per square meter) you will basically need 300gms of resin to wet it out. A little more is always a safe bet. I use what is called the wet method to apply the fiberglass and resin. This involves wetting out the area of ply I am going to lay up first. For the first mix, I add acetone at a rate of no more than 10%. This thins the epoxy and allows it to soak further into the plywoods grain. I allow it to soak for about 10 minutes. This helps expel any unwanted air from the plywood itself and allows the acetone to evaporate off. It also allows the resin to get a good soak into the plywood. With Bote coat, I have 45-50 minutes gel time so this leaves me with about 35-40 minutes. Next I apply the cloth. I find it sticks pretty well to the previously wet surface, even when vertical. Using a 4" brush I wet out the corners and harder spots with a dabbing motion. I use a fine 200mm paint roller for the flat areas where possible. I wet it out evenly until the cloth is transparent repeating the process if applying more than one layer.

Next is the most crucial part. I use an aluminum roller as shown above, working from one end rolling it back and forth over the cloth to expel the unwanted air, ensuring I have completely filled the weave with resin. Once complete I then wash my rollers and brushes out in acetone.

With epoxy resin, it is required to sand in between coats once the resin has fully cured for correct adhesion. Above shows the end panels (left) with a quick sanding before laying up the rest of the tank.

The sanding continues. This part was the most time consuming but had to be done. I didn't want any delamination between coats

The picture above shows the final layer of cloth being applied to the bottom. With the fiberglass complete, it was time to concentrate on the extra layers of epoxy to ensure a perfect seal.

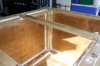

Final coats on and looking the part.

All up there is 1 layer of 300gsm cloth over all the flat areas with an additional layer over all the internal corners which lap onto the flat areas by about 4". The top braces have two layers of cloth to beef them up as well. Next were 2 coats of epoxy resin with a good sanding in between, sanded again and another 3 coats which were applied in succession before the previous coat was cured. Epoxy will get a chemical bond if you apply the next coat before the previous has cured.

The center piece for the tank.

Again but in the tank. I needed to make sure it could fit through the top opening. Success!

That is a 13.4oz/380g bag of Massivore for size reference.

While I was waiting for the glass, I got busy with the plumbing and lids. I kept it pretty simple opting for several large canisters for this build. I have since added a DIY sump/filter out of a 200L polyethylene esky. More on that later. I drilled the spray rail with a total of 31 holes. Their combined area was just a little less than the 3 return pipes so I could fine tune it at a later date. They have stayed this way and seem to work great. Also, notice the holes in the inlet pipes just below the spray rail. This will break the siphon should a canister spring a major leak. Without this, it could drain right down to the bottom of the inlet pipe. Something we should all do with our canister setups. This way, the tank can only drain to those holes should something go wrong.

An outside view of the plumbing.

I used clear polycarbonate from Laserlite. Guaranteed against hail damage and UV treated. They have worked out well. A big concern was how to secure them to prevent any fish performing a Harry Houdini on me but that problem was easily solved with a simple pipe system and has worked extremely well. It is an easy process to just slide the pipes to the side and then lift out the lid. For general feeding, I just push the food between the lid and the tank.

Most of the glass thickness calculators all came out at the same requirement of 16mm for this build. I probably could have saved some money and used 15mm but I would rather over build and know it is safer so 19mm it was. I made a cradle in anticipation of its arrival. This piece weighed close to 100kg.

The next job was to get the glass into the tank. For this I had to roll the tank onto its back and bring the glass in from one side between the top support beam and end in an upright position. I propped it against the bottom on a make shift cradle which was at this stage upright, then rolled the tank back upright. The glass and cradle were now lying on the floor. It is probably a good time to point out when building a tank that has all its top cross braces in place prior to glass installation, one has to make sure the top opening is wider than the glass sheet is tall. Failure of this will stop you getting your glass into the tank.

Before sealing the glass in place, I raised the tank onto its blocks and got it level. I had to cut timber shims to go between the tank and blocks as the concrete was far from level.

I used a product from Selleys which is 100% silicone designed for glass and aquariums. I wasn't too concerned with the best of the best silicones as the glass was to be supported by a substantial frame and would have the water pressure pushing against the seal. I used a total of 8 tubes. This process was pretty easy. I gave the tank a quick scuff and cleaned everything thoroughly with acetone. With the help of my son, I got the glass in an upright position. I had it resting on some small pieces of soft rubber so the glass was not on the fiberglass. My son held it at enough angle for me to run an even bead around the glass and we pushed it into place being careful to get an even bedding. Once I had it propped, I ran a second bead around the inside and cleaned up the outside.

Seven cure days later and it was time to fill. The picture above shows the internal heaters in there holders. Heaters are 2 x 300W and 1 x 200W. So far I have only had the two 300W heaters plugged in and it has kept a very steady temperature.

Lighting was kept simple as described in the above picture.

Filtration now consists of 3 x AquaPro CFD2600 canisters. I already had these so I put them to use. As stated earlier, I have since added a DIY sump/filter out of a 200L polyethylene esky. It has an added advantage of being insulated. It is fed via a 2" bottom feed diy overflow with a 3000 l/ph pump for the return. The filters and sump run a mixture of Seachem Matrix, ceramic rings and Aquaclay for biological filtration and plenty of filter floss for mechanical. The bucket that is sealed into the esky lid holds the filter floss for the sump. It also has an overflow installed in the bucket should the filter floss become too clogged. The bucket idea makes it easy to change out the filter floss without having to open up the esky. I also run 2 power heads for added water flow.

Because I can't see into the esky like a regular sump to see where the water level is I had to make a diy gauge. I made use of simple sealed pipe within another pipe that floats to a previously marked line. Simple but effective.

A few pictures and a video of the tank and stock combined.

[YT]<object width="480" height="385"><param name="movie" value="http://www.youtube.com/v/WSBGNn_Odbk&hl=en_GB&fs=1&"></param><param name="allowFullScreen" value="true"></param><param name="allowscriptaccess" value="always"></param><embed src="http://www.youtube.com/v/WSBGNn_Odbk&hl=en_GB&fs=1&" type="application/x-shockwave-flash" allowscriptaccess="always" allowfullscreen="true" width="480" height="385"></embed></object>[/YT]

It has been about 6mths since I first filled it up and I am happy to say that it has been a huge success. I highly recommend people try their hand at the DIY side of fish keeping. There are plenty of methods to achieve a larger than normal tank and I must say, it is a good feeling of achievement when looking at your own personally built creation.

Brenton Smith.[/QUOTE]

First up, a final design picture and the tank as blue prints for anyone interested.

Above is how I made use of 4 sheets without the need for extra lumber for framing.

These measurements are for a 2700mm x 1200mm x 32mm sheet. If your sheets are thinner or thicker, the measurements will inevitably change. External dimension are 2700mm x 1200mm x 1032mm. That equates to 885 gallon but for the sake of simplicity, I call it an 800g as this is what it actually holds going by internal measurements.

The materials required for this build are as such.

Float glass - 2400mm x 850mm x 19mm supplied by http://www.aquariumsrus.com.au

4 Ply sheets - 2700mm x 1200mm x 32mm

Roofing screws

Builders bog

30m x 1m x 300gsm woven roving cloth

18L Boat Cote Epoxy supplied by http://boatcraft.com.au

Black epoxy pigment

4L Acetone for clean up

8 tubes of Silicone

2 clear polycarbonate roofing sheets - 2400mm x 1200mm

2 pvc pipes 3000mm x 25mm for lid hold down only

36 Besser blocks for stand

Sand paper, brushes and general work tools etc.

There were two reasons I opted to use such thick sheets. The first and major reason was to eliminate external bracing altogether. I wanted a somewhat clean appeal to the outside of the tank as well as inside. The second was to help insulate the tank, high on my list of priorities as this build was always intended to be outside. Under cover but still subject to the ambient air temps outside.

With my design in hand, it was time to start ripping these sheets up. You can see above the 98mm rips to the side. When ripping plywood I use a second sheet as a guide. Use a couple of nails to hold it in place but be sure to leave them proud for easy removal once your cut is done.

With the long 98mm rips done it was time to cut out the window. First job was to mark it out, double check it and then drill out the corners with a 45mm OD hole saw. I wanted a nice round corner here not so much for looks but to make it easier to fiberglass at a later date.

With the power saw, I cut out the window freehand and cut the last little bit in the corners with a hand saw. Now with the inside of the window out, I went back to using a sheet as a guide to cut it into the remaining braces.

The main sides went together fairly fast. My son was a big help in this build. I think he enjoyed it immensely. Construction of anything can make for great father/son bonding sessions.

Here is the bottom plate completely screwed off. All screws are counter sunk and pre drilled. Time consuming but a must.

This picture shows the top cross braces well. It also shows the infill pieces between them. I left a recess for the lids to sit in as I wanted them to sit flush with the top of the tank.

All the internal corner braces are in and it is now completely screwed off.

Time to fill all the screws and round off all corners both internal and external. I just used a builders bog for this. Bog is not the best choice for use near water but if water gets to it, it will also get to the ply which means I have a serious problem anyway making it a mute point.

Getting the corners filleted out and rounded off aids in the fiberglassing process later so plenty of time was spent in this part of the preparation.

Fiberglass? I chose this route as I am comfortable working with this medium and it will allow me to construct without the need for external framing. It has exceptional strength, durability and impact resistant properties and applied correctly will last many, many years.

Resin? I believe that if a product is designed specifically for timber boat building, it will be perfect for a plywood aquarium so Bote Cote Epoxy was the choice for this build. On par with West Systems but I find it better in a couple of ways. I would say equal in quality but easier in terms of use. It has a simple 2:1 mix ratio and is a little thicker in viscosity. The main thing I like with Bote Cote is its Hardeners. They are free of the side reaction known as Amine Blush. For those that don't know what that is, it is a residue that forms on the surface of many epoxy resins when they are used in colder or damp conditions. It is a real pain to remove usually having to be scrubbed off with solvents or an ammonia based cleaner before you can continue with sanding, let alone applying the next coats. Bote Cote being free of this means just a simple sand in between coats for correct adhesion is sufficient.

You can see from the pictures above that the resin is already black. I used a pigment to colour the resin as epoxy resins don't have gel coats for a top coat like polyester/vinyl ester resins.

Fibre glassing method? First thing I do is to have all my cloth cut up and ready for all the areas to be glassed. I also make sure the epoxy resin both part A & B are pre warmed to make it easier to work with. I usually mix up about the same amount of resin in weight as the cloth I am using, maybe a little more. e.g. If your cloth is 300gsm (grams per square meter) you will basically need 300gms of resin to wet it out. A little more is always a safe bet. I use what is called the wet method to apply the fiberglass and resin. This involves wetting out the area of ply I am going to lay up first. For the first mix, I add acetone at a rate of no more than 10%. This thins the epoxy and allows it to soak further into the plywoods grain. I allow it to soak for about 10 minutes. This helps expel any unwanted air from the plywood itself and allows the acetone to evaporate off. It also allows the resin to get a good soak into the plywood. With Bote coat, I have 45-50 minutes gel time so this leaves me with about 35-40 minutes. Next I apply the cloth. I find it sticks pretty well to the previously wet surface, even when vertical. Using a 4" brush I wet out the corners and harder spots with a dabbing motion. I use a fine 200mm paint roller for the flat areas where possible. I wet it out evenly until the cloth is transparent repeating the process if applying more than one layer.

Next is the most crucial part. I use an aluminum roller as shown above, working from one end rolling it back and forth over the cloth to expel the unwanted air, ensuring I have completely filled the weave with resin. Once complete I then wash my rollers and brushes out in acetone.

With epoxy resin, it is required to sand in between coats once the resin has fully cured for correct adhesion. Above shows the end panels (left) with a quick sanding before laying up the rest of the tank.

The sanding continues. This part was the most time consuming but had to be done. I didn't want any delamination between coats

The picture above shows the final layer of cloth being applied to the bottom. With the fiberglass complete, it was time to concentrate on the extra layers of epoxy to ensure a perfect seal.

Final coats on and looking the part.

All up there is 1 layer of 300gsm cloth over all the flat areas with an additional layer over all the internal corners which lap onto the flat areas by about 4". The top braces have two layers of cloth to beef them up as well. Next were 2 coats of epoxy resin with a good sanding in between, sanded again and another 3 coats which were applied in succession before the previous coat was cured. Epoxy will get a chemical bond if you apply the next coat before the previous has cured.

The center piece for the tank.

Again but in the tank. I needed to make sure it could fit through the top opening. Success!

That is a 13.4oz/380g bag of Massivore for size reference.

While I was waiting for the glass, I got busy with the plumbing and lids. I kept it pretty simple opting for several large canisters for this build. I have since added a DIY sump/filter out of a 200L polyethylene esky. More on that later. I drilled the spray rail with a total of 31 holes. Their combined area was just a little less than the 3 return pipes so I could fine tune it at a later date. They have stayed this way and seem to work great. Also, notice the holes in the inlet pipes just below the spray rail. This will break the siphon should a canister spring a major leak. Without this, it could drain right down to the bottom of the inlet pipe. Something we should all do with our canister setups. This way, the tank can only drain to those holes should something go wrong.

An outside view of the plumbing.

I used clear polycarbonate from Laserlite. Guaranteed against hail damage and UV treated. They have worked out well. A big concern was how to secure them to prevent any fish performing a Harry Houdini on me but that problem was easily solved with a simple pipe system and has worked extremely well. It is an easy process to just slide the pipes to the side and then lift out the lid. For general feeding, I just push the food between the lid and the tank.

Most of the glass thickness calculators all came out at the same requirement of 16mm for this build. I probably could have saved some money and used 15mm but I would rather over build and know it is safer so 19mm it was. I made a cradle in anticipation of its arrival. This piece weighed close to 100kg.

The next job was to get the glass into the tank. For this I had to roll the tank onto its back and bring the glass in from one side between the top support beam and end in an upright position. I propped it against the bottom on a make shift cradle which was at this stage upright, then rolled the tank back upright. The glass and cradle were now lying on the floor. It is probably a good time to point out when building a tank that has all its top cross braces in place prior to glass installation, one has to make sure the top opening is wider than the glass sheet is tall. Failure of this will stop you getting your glass into the tank.

Before sealing the glass in place, I raised the tank onto its blocks and got it level. I had to cut timber shims to go between the tank and blocks as the concrete was far from level.

I used a product from Selleys which is 100% silicone designed for glass and aquariums. I wasn't too concerned with the best of the best silicones as the glass was to be supported by a substantial frame and would have the water pressure pushing against the seal. I used a total of 8 tubes. This process was pretty easy. I gave the tank a quick scuff and cleaned everything thoroughly with acetone. With the help of my son, I got the glass in an upright position. I had it resting on some small pieces of soft rubber so the glass was not on the fiberglass. My son held it at enough angle for me to run an even bead around the glass and we pushed it into place being careful to get an even bedding. Once I had it propped, I ran a second bead around the inside and cleaned up the outside.

Seven cure days later and it was time to fill. The picture above shows the internal heaters in there holders. Heaters are 2 x 300W and 1 x 200W. So far I have only had the two 300W heaters plugged in and it has kept a very steady temperature.

Lighting was kept simple as described in the above picture.

Filtration now consists of 3 x AquaPro CFD2600 canisters. I already had these so I put them to use. As stated earlier, I have since added a DIY sump/filter out of a 200L polyethylene esky. It has an added advantage of being insulated. It is fed via a 2" bottom feed diy overflow with a 3000 l/ph pump for the return. The filters and sump run a mixture of Seachem Matrix, ceramic rings and Aquaclay for biological filtration and plenty of filter floss for mechanical. The bucket that is sealed into the esky lid holds the filter floss for the sump. It also has an overflow installed in the bucket should the filter floss become too clogged. The bucket idea makes it easy to change out the filter floss without having to open up the esky. I also run 2 power heads for added water flow.

Because I can't see into the esky like a regular sump to see where the water level is I had to make a diy gauge. I made use of simple sealed pipe within another pipe that floats to a previously marked line. Simple but effective.

A few pictures and a video of the tank and stock combined.

[YT]<object width="480" height="385"><param name="movie" value="http://www.youtube.com/v/WSBGNn_Odbk&hl=en_GB&fs=1&"></param><param name="allowFullScreen" value="true"></param><param name="allowscriptaccess" value="always"></param><embed src="http://www.youtube.com/v/WSBGNn_Odbk&hl=en_GB&fs=1&" type="application/x-shockwave-flash" allowscriptaccess="always" allowfullscreen="true" width="480" height="385"></embed></object>[/YT]

It has been about 6mths since I first filled it up and I am happy to say that it has been a huge success. I highly recommend people try their hand at the DIY side of fish keeping. There are plenty of methods to achieve a larger than normal tank and I must say, it is a good feeling of achievement when looking at your own personally built creation.

Brenton Smith.[/QUOTE]