Okay, here goes.

I did a practice tank before this one to make sure that I have the skills to do this tank. Here's a link. The practice did help a lot, but it didn't prepare me for the biggest challenge of this tank... SIZE! An 8' 300 Gallon tank is HUGE and very HEAVY! I had to lug this tank in and out of my flat every time I wanted to work on it. Very very very frustrating.

Okay, here is the wood for the tank. I used the 2x4s for a temporary work bench for this project.

Here's a pic of some screws ready to be driven in.

One side done, lining up next side.

Here's the tank outside with a layer of fiberglass. Not my best fiber glassing effort to date. You can notice the white blotches here and there... I did however go over every thing a second time with the polyester resin, and that sorted the "dry fiberglass" parts.

Here you can see the bottom of the tank. When I installed the bottom piece, it pulled the tank frame nice and square. At this point the tank also has 4 layers of epoxy over the fiberglass layer. The day this pic was taken, I dropped a chisel into the tank by accident. The tip of the chisel chipped the epoxy, but the fiberglass layer remained intact. So the tank should be able to survive a couple of bumps here and there. You can also notice the thing I'm the proudest of; all the parts fit together via miter cuts, thus hiding all the "open edges" of the plywood. Cutting those miter cuts was a LOT of work.

These two pics show the hole for the drain. All the epoxy and fiberglass layers made that area VERY uneven. So I fashioned a sander and sanded it level. Then I put a layer of epoxy over it again.

I hate this pic! I was handling the piece of glass for the front of the tank when I gave it the slightest, softest bump on the floor... oops. That little bump is gonna cost me +- $200. Nice...

Here's the tank. Inside the flat and OUT! It is SO heavy to lug around alone.

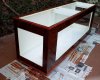

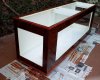

And here's the sump for the tank

Updates might be few and far between from here on out, since someone will have to buy some new glass before the project can continue...

I did a practice tank before this one to make sure that I have the skills to do this tank. Here's a link. The practice did help a lot, but it didn't prepare me for the biggest challenge of this tank... SIZE! An 8' 300 Gallon tank is HUGE and very HEAVY! I had to lug this tank in and out of my flat every time I wanted to work on it. Very very very frustrating.

Okay, here is the wood for the tank. I used the 2x4s for a temporary work bench for this project.

Here's a pic of some screws ready to be driven in.

One side done, lining up next side.

Here's the tank outside with a layer of fiberglass. Not my best fiber glassing effort to date. You can notice the white blotches here and there... I did however go over every thing a second time with the polyester resin, and that sorted the "dry fiberglass" parts.

Here you can see the bottom of the tank. When I installed the bottom piece, it pulled the tank frame nice and square. At this point the tank also has 4 layers of epoxy over the fiberglass layer. The day this pic was taken, I dropped a chisel into the tank by accident. The tip of the chisel chipped the epoxy, but the fiberglass layer remained intact. So the tank should be able to survive a couple of bumps here and there. You can also notice the thing I'm the proudest of; all the parts fit together via miter cuts, thus hiding all the "open edges" of the plywood. Cutting those miter cuts was a LOT of work.

These two pics show the hole for the drain. All the epoxy and fiberglass layers made that area VERY uneven. So I fashioned a sander and sanded it level. Then I put a layer of epoxy over it again.

I hate this pic! I was handling the piece of glass for the front of the tank when I gave it the slightest, softest bump on the floor... oops. That little bump is gonna cost me +- $200. Nice...

Here's the tank. Inside the flat and OUT! It is SO heavy to lug around alone.

And here's the sump for the tank

Updates might be few and far between from here on out, since someone will have to buy some new glass before the project can continue...

)

)