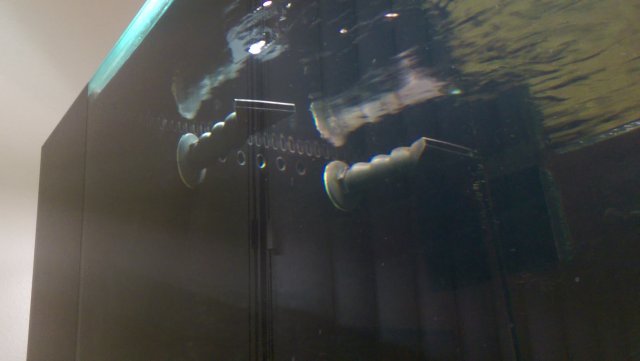

The advantage of this design applies almost exclusively for tanks that serve as room dividers or where the tanks are visible from all sides. With the return coming up through the overflow box, absolutely no plumbing is visible in the tank. This picture is from Midwest Custom Aquarium's gallery.

Really no advantage if the back of your tank is not visible. We plumbed our 300 gallon tank this way for the return from our mechanical filtration. We drilled three holes in the top of our tank to accommodate other filtration. I personally have an aversion to drilling the back of the tank. Our brutes have broken three bulkheads. We would have been in trouble if the bulkheads had been on the back of the tank.

Have the builder put in the holes for you. We had our big tank built with eleven holes on the top of the tank. On a side note, carefully inspect your tank before you accept it. Once you sign for it and the trucker leaves, it will be too late. It will be a real hassle, because the trucker will be in a hurry to leave, and the tank will be really packed up and on a couple of pallets. We were instructed to inspect the tank before signing for it. We did not do that. Husband was in school, and it was a month or so later before we unpacked the tank and discovered a crack in the floor of the tank starting at the corner of the left overflow box. One of the pallets was damaged--probably a forklift fork coming up through the pallet and stressing the floor of the tank. We were able to repair the crack, and the builder was gracious to send us acrylic pieces and Weldon.

When your tank is crated up, the trucker will be very annoyed if you insist on inspecting the tank. Do it anyway--you have a lot to potentially lose if you don't.