Hey, so after a bit of a false alarm with my secondhand 120 gallon tank's seals (it's been holding water for a little less than a week with no incident), I'm back to the task of figuring out how I'm going to handle the filtration and plumbing.

While it's by no means necessary for a tank of this size, I'm a fan of moving bed style filtration because of the low maintenance requirements, the high efficiency, and the high ratio of atmospheric oxygen vs dissolved oxygen the filter uses.

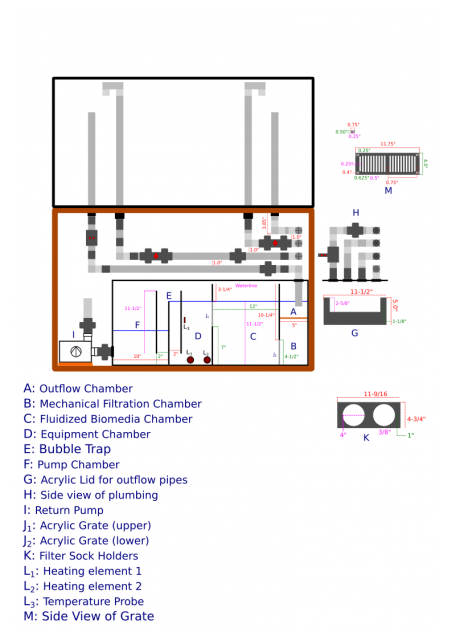

Below is my current plan for my sump. It's a somewhat unorthodox design in that the mechanical filtration comes after the biological filtration, but I've seen other people with moving beds doing in like this since it won't get gummed up with detritus like a wet/dry or submerged biofilter would, and the flow of water coming down from the tank can apparently help drive the motion of the media, reducing the size of the air pump you need to run the system. I'm planning on having a final flow rate of 720 GPH, well within the recommended limits for K1 to ensure good contact time, and I've sized the chamber for a capacity of around 16 liters of media (forgive me for mixing metric and imperial units) based on a 60:40 K1:Water ratio. The air pump I'm planning on using is a high-end 16 LPM pump that's supposedly extremely quiet for a pump of its size, and I've heard you want about 1 LPM of air for each liter of media.

Can anyone with experience using this style of filtration offer advice on how I can further refine this design, and how I should set up the air lines to achieve the best results?

While it's by no means necessary for a tank of this size, I'm a fan of moving bed style filtration because of the low maintenance requirements, the high efficiency, and the high ratio of atmospheric oxygen vs dissolved oxygen the filter uses.

Below is my current plan for my sump. It's a somewhat unorthodox design in that the mechanical filtration comes after the biological filtration, but I've seen other people with moving beds doing in like this since it won't get gummed up with detritus like a wet/dry or submerged biofilter would, and the flow of water coming down from the tank can apparently help drive the motion of the media, reducing the size of the air pump you need to run the system. I'm planning on having a final flow rate of 720 GPH, well within the recommended limits for K1 to ensure good contact time, and I've sized the chamber for a capacity of around 16 liters of media (forgive me for mixing metric and imperial units) based on a 60:40 K1:Water ratio. The air pump I'm planning on using is a high-end 16 LPM pump that's supposedly extremely quiet for a pump of its size, and I've heard you want about 1 LPM of air for each liter of media.

Can anyone with experience using this style of filtration offer advice on how I can further refine this design, and how I should set up the air lines to achieve the best results?