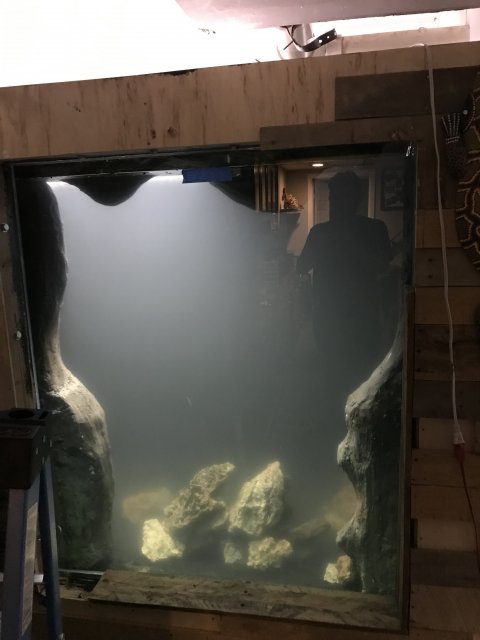

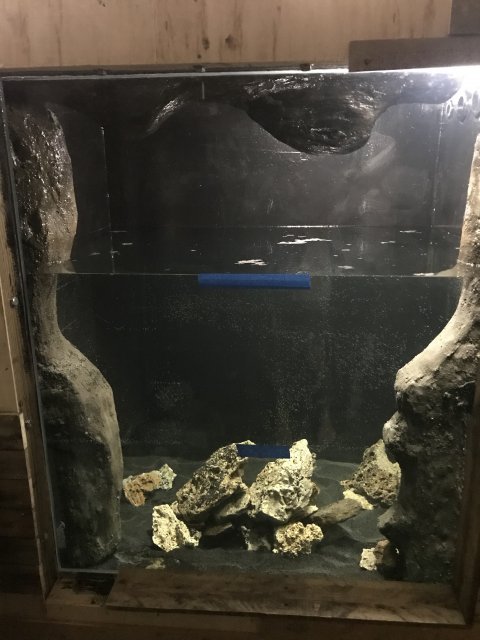

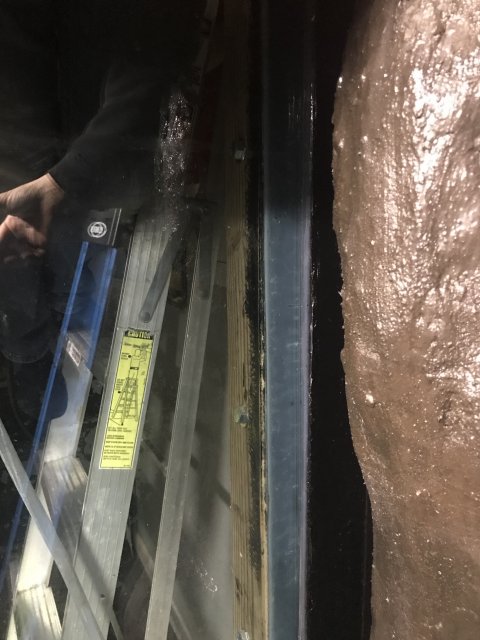

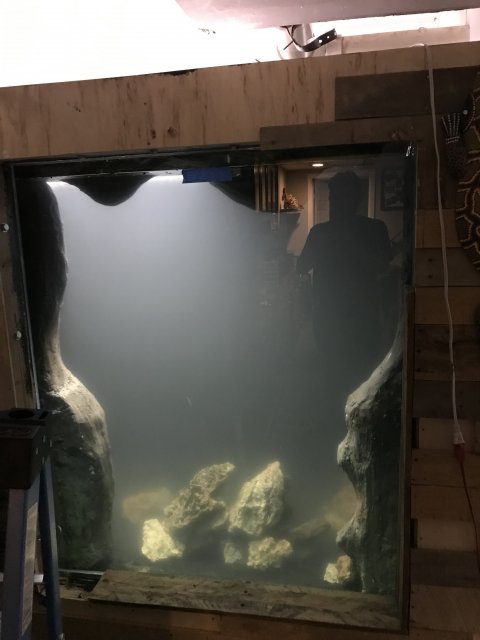

I constructed a 500 gallon plywood tank in my basement which is tucked into the corner so just the front panel with the glass is exposed. It measures 4’ deep, 5’ tall and 5’ wide. The front glass panel is 54” wide x 46” tall and 1 1/4” thick. The tank when full of water would only be about 52” to the top of the water. The tank was constructed with 2x4 at 12” on center with 3/4” sanded plywood. The front corner has a 4x4 post on either end with lag bolts going in opposite direction to tie in the walls. There are also lags in the bottom plate of the walls every 18” and lags all around the front glass panel every 12”. The base of the tank was constructed with 2x6 at 12” on center with extra bracing between them. The floor of the tank has 3 sheets of 1/2” plywood then a final sheet of 3/4”. The bracing at the top is three 2x6 that run from front to back. One in the center and the others on either end. The front glass panel sits in a frame inside the tank which is 1 1/4” deep. The tank was sealed with pond armor. All the corners have fiberglass mess. I did a minimum of 4 coats with a couple of extra heavy coats in the corners.

I recently water tested it by filling it 1/3rd of the way up. I ran a pump inside the tank to circulate water and had no leaking after 4 days. I drained it and set it up. I refilled it to the same mark and let it sit for 3 days then filled it up to 2/3rds full. No leaking for another 4 days. I now had it not leak for over a week and a half. I filled it up another 6” no leaking. At this point I’m 6” from my top water line. I filled it another 3”. 5 hours later I came to check it and about 12” of water was missing. I noticed leaking from the front corner. My wife and began to drain it. At the halfway point it stopped leaking.

I drained the tank down to a few inches. I inspected the tank but I can’t find any obvious cracks or holes. All the expoy seems look fine. My only thought is the joint between the glass and wood on the inside. I’m thinking I might need to remove all the silicone from the joint between the glass and the frame in which the glass sits. Unfortunately I can’t disassemble the tank to figure it out because of the way it’s built and I don’t see any other problems. I do plan on removing the rocks and sand to thoroughly inspect the tank.

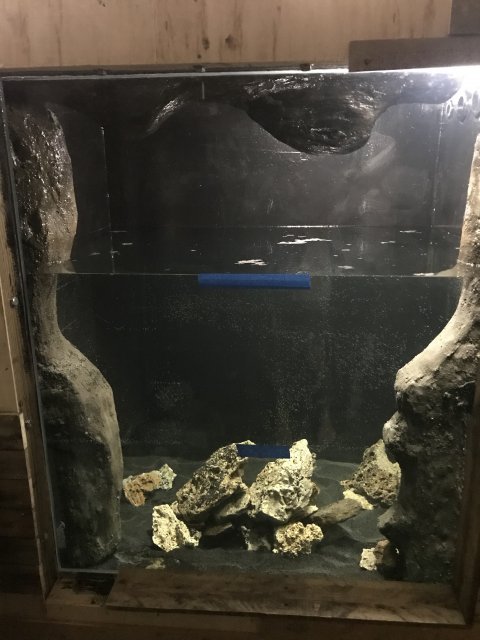

move attached a few photos of the tank with water and without. I can take some others of the inside if that would help.

Any advice would be greatly appreciated.

I recently water tested it by filling it 1/3rd of the way up. I ran a pump inside the tank to circulate water and had no leaking after 4 days. I drained it and set it up. I refilled it to the same mark and let it sit for 3 days then filled it up to 2/3rds full. No leaking for another 4 days. I now had it not leak for over a week and a half. I filled it up another 6” no leaking. At this point I’m 6” from my top water line. I filled it another 3”. 5 hours later I came to check it and about 12” of water was missing. I noticed leaking from the front corner. My wife and began to drain it. At the halfway point it stopped leaking.

I drained the tank down to a few inches. I inspected the tank but I can’t find any obvious cracks or holes. All the expoy seems look fine. My only thought is the joint between the glass and wood on the inside. I’m thinking I might need to remove all the silicone from the joint between the glass and the frame in which the glass sits. Unfortunately I can’t disassemble the tank to figure it out because of the way it’s built and I don’t see any other problems. I do plan on removing the rocks and sand to thoroughly inspect the tank.

move attached a few photos of the tank with water and without. I can take some others of the inside if that would help.

Any advice would be greatly appreciated.