Patio Tanks Rock!

- Thread starter Ulu

- Start date

A few weeks ago, the rainy season started, this means deluges every day that wash tannins into the tank from surrounding foliage.

Even with daily water changes I can't keep up with the tannins and they are so thick I haven't been able to see the tank inhabitants unless they brush close up against the front glass.

The Dieffenbachia roots became so long and flowing they started to clog the overflows, so the plant had to be moved to the front of the tank.

And the sumps are also targets for rain dripping tannins.

I hope to remove the papyrus from the sump and transfer them to the 50 gal once its fixed.

Even with daily water changes I can't keep up with the tannins and they are so thick I haven't been able to see the tank inhabitants unless they brush close up against the front glass.

The Dieffenbachia roots became so long and flowing they started to clog the overflows, so the plant had to be moved to the front of the tank.

And the sumps are also targets for rain dripping tannins.

I hope to remove the papyrus from the sump and transfer them to the 50 gal once its fixed.

Do you want all those tannins? I think I'd put a rain deflector up.

Is there much wind? We're getting unusual wind patterns of cool air.

I think cold melt water from the arctic is cooling the west coast.

But maybe hot plumes in volcanic regions are twisting the atmosphere.

Is there much wind? We're getting unusual wind patterns of cool air.

I think cold melt water from the arctic is cooling the west coast.

But maybe hot plumes in volcanic regions are twisting the atmosphere.

The tannins are thicker than I'd like for viewing, but it seems they are a regular seasonal occurrence here, so I wonder if the temporary anti- bacterial properties help purge the fish of certain natural microbial parasites, or populations or bacteria that could become pathogenic if left unchecked.

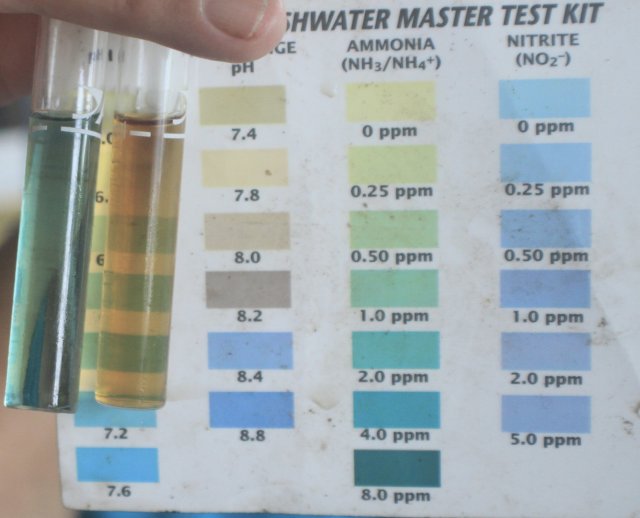

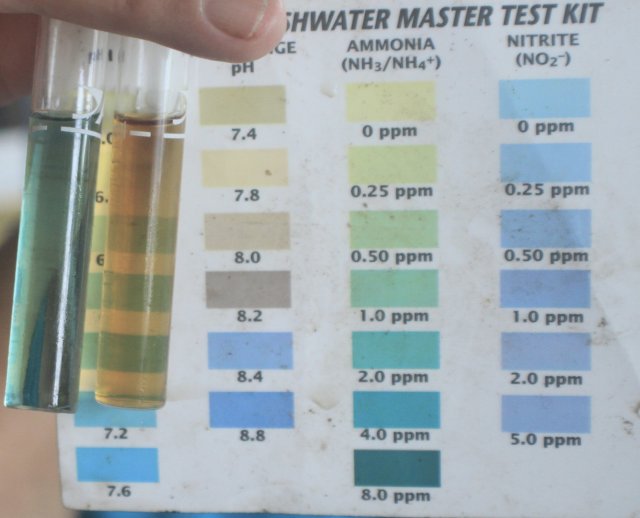

I'm surprised that the pH of the tank hasn't dropped in any significant way.

Normal pH is 8-8.2, and when I tested for pH the other day, it was much closer than I expected.

I ran both low and high range pH.

The jug of tank water is just before I started daily diluting.

I'm surprised that the pH of the tank hasn't dropped in any significant way.

Normal pH is 8-8.2, and when I tested for pH the other day, it was much closer than I expected.

I ran both low and high range pH.

The jug of tank water is just before I started daily diluting.

What did I learn from having a patio tank?

I want more algae.

So far it seems all my algae is going to grow outside in the sunlight, and none of it is going to grow in the house, as the lighting in my TV room is dim where the aquarium is located. And I keep plecos indoors.

But I also learned that I should let that outdoor algae grow, because it is reducing the nitrates more than pothos or other plants I have growing from the tank.

Having a 14 inch Pleco in the tank I want to grow algae in is not working for me very well either.

I want more algae.

So far it seems all my algae is going to grow outside in the sunlight, and none of it is going to grow in the house, as the lighting in my TV room is dim where the aquarium is located. And I keep plecos indoors.

But I also learned that I should let that outdoor algae grow, because it is reducing the nitrates more than pothos or other plants I have growing from the tank.

Having a 14 inch Pleco in the tank I want to grow algae in is not working for me very well either.

Since first posting in this thread, I have gone from using smallish sumps, to a 125 gal tank as a sump/refugium for my 180 gal tank.

The pump and filtration (Porrett foam, and a few bags of biomedia) sit in less than a foot of one end, and are hidden by a plant outside the tank. the The rest is a planted refugium, making the sump almost like an extra tank, enjoyable to look at with its array of plants, and large population of shrimp.

I am also an algae lover for its ability to consume nitrate so it is allowed to grow everywhere except the front glass (except if I'm lackadaisical about scraping with the Xacto blade).

l

also encourage it on rocks and wood pieces.

The pump and filtration (Porrett foam, and a few bags of biomedia) sit in less than a foot of one end, and are hidden by a plant outside the tank. the The rest is a planted refugium, making the sump almost like an extra tank, enjoyable to look at with its array of plants, and large population of shrimp.

I am also an algae lover for its ability to consume nitrate so it is allowed to grow everywhere except the front glass (except if I'm lackadaisical about scraping with the Xacto blade).

l

also encourage it on rocks and wood pieces.

That’s pretty green, but I could use a lot more.

Temps go from 105F in the afternoon to 62F by 6 AM so I am actually covering my outdoor 55 & 30g tanks with solar screen, except in the morning, so they don’t get too much heat.

And I am foolishly trying to reduce the algae.

They only catch strong sun from about 3PM to 5PM, so I might do away with the cover, as the water all comes indoors to the 125, where it’s air-conditioned to 78° most of the time. The 125 sets on masonry and so that really stabilizes the temperature of the system a lot. Also the wall behind that tank is an exterior wall and I have it triple insulated with fiberglass bats and two sheets of Styrofoam.

I see tank temps above 82 indoors, if it is ~110 outdoors, and normally it’s all closer to 78F. I do have to run the heaters part of the year. For June July and August however I just unplug them.

Anyhow so far I’m pretty happy with the system and the fact that my show tank is algae free. I don’t really think that is going to change as the amount of algae in the outdoor tanks increases. I think the only thing that’s going to happen is that my ammonia & nitrate levels are going to drop.

Temps go from 105F in the afternoon to 62F by 6 AM so I am actually covering my outdoor 55 & 30g tanks with solar screen, except in the morning, so they don’t get too much heat.

And I am foolishly trying to reduce the algae.

They only catch strong sun from about 3PM to 5PM, so I might do away with the cover, as the water all comes indoors to the 125, where it’s air-conditioned to 78° most of the time. The 125 sets on masonry and so that really stabilizes the temperature of the system a lot. Also the wall behind that tank is an exterior wall and I have it triple insulated with fiberglass bats and two sheets of Styrofoam.

I see tank temps above 82 indoors, if it is ~110 outdoors, and normally it’s all closer to 78F. I do have to run the heaters part of the year. For June July and August however I just unplug them.

Anyhow so far I’m pretty happy with the system and the fact that my show tank is algae free. I don’t really think that is going to change as the amount of algae in the outdoor tanks increases. I think the only thing that’s going to happen is that my ammonia & nitrate levels are going to drop.

Currently I am running two 7 inch dia filter socks in the Brute sump, and another one in the 30g pump chamber, so the water gets filtered going into the brute and out of it as well.

But today it got a DIY moving bed sand filter.

I was running a store bought sand filter a while back, but it had failures due to exposure to the sun, and so I decided this time I would hide my filter inside the Brute.

Because the entire thing (except for the electrical plug) is underwater, I don’t have to worry about leakage. I used press fit drip Irrigation fittings and pipe & if they drip a little bit it won’t matter. They were cheap and easy to put together requiring no glue.

Here’s the sand filter standing up on the edge of the sump, so you can actually see it. The pump is running and the sand churns up about 3 inches.

This has a two chamber design with a baffle in the middle. The water enters through a pipe that goes all the way to the bottom of the sand and the water flows out from a simple elbow fitting glued into the top.

This has a two chamber design with a baffle in the middle. The water enters through a pipe that goes all the way to the bottom of the sand and the water flows out from a simple elbow fitting glued into the top.

Here is the sand filter under water in the sump. The pump is invisible at the bottom of the sump, below the filter socks. This helps draw water to the bottom of the sump.

I know it’s pretty impossible to tell what’s going on in that photo. The two flex hoses come from my 125 and 55 gallon tanks and they overflow directly into these big filter socks. The socks are just held in place with some zip ties and a piece of plastic tubing.

The three-quarter inch black tubing is poly propylene irrigation drip line. I used a little push on valve so I could control the flow and not blow excess sand into my filter sock. The smaller clear vinyl tube is the outflow from the sand filter and it goes into the left filter sock.

Having the entire system contained within the brute filter and completely underwater has other advantages besides containment of any drips.

Because there is no head pressure in the system anywhere when the pump is off, you do not have to worry about sand backing up into the pump should the system shut off. I turned it on and off several times and it starts right back up.

The other thing is that, should a hose pop off, the worst thing that can happen is that sand can wind up in the bottom of my Brute, And in the pump chamber filter sock.

If the hoses were external to the Brute, and one popped off at midnight, the system would blow 100 gallons of water out onto the ground before I woke up in the morning.

The sand I used was aragonite sand that I bought previously for my Cichlid tank, but I found that they like to dig it up way too much.

The two sand chambers are snack containers from the grocery store. It just so happens that the lids fit perfectly with a 4 inch sink strainer rubber washer and I used three of them to seal the system. There is a rubber washer between each cap and chamber and there was another rubber washer between the two caps which are back to back.

Those caps are clamped together inside by a 1.5 inch bulkhead fitting, which serves to baffle the chambers but still allow plenty of water flow. The blow tube is ordinary three-quarter inch drip irrigation pipe and I used epoxy putty to glue the roughened fittings into roughened holes in the PETE plastic snack containers.

I used Otey plumbers epoxy putty to hold the fittings. I have used this before on filters, but it tends to degrade after about five years under water. This may be due to something in the feed as I noticed it also turning a pink color, perhaps from the dye used in cheap fish food.

I know it will take a while for the sand to cycle in and although it is not brand new It has been out of the tank for months. Anyhow the system is running well I am hoping that it will improve things once it aGes. I did not take pictures of the construction, And I did not describe every part of it because I don’t attend this to be a how-to. I have tested the snack containers and they will take considerable pressure but the cap itself is the weak link.

One of these things could blow up in your face. They are strong but they don’t have the same quality control as a pressure vessel.

But today it got a DIY moving bed sand filter.

I was running a store bought sand filter a while back, but it had failures due to exposure to the sun, and so I decided this time I would hide my filter inside the Brute.

Because the entire thing (except for the electrical plug) is underwater, I don’t have to worry about leakage. I used press fit drip Irrigation fittings and pipe & if they drip a little bit it won’t matter. They were cheap and easy to put together requiring no glue.

Here’s the sand filter standing up on the edge of the sump, so you can actually see it. The pump is running and the sand churns up about 3 inches.

This has a two chamber design with a baffle in the middle. The water enters through a pipe that goes all the way to the bottom of the sand and the water flows out from a simple elbow fitting glued into the top.

This has a two chamber design with a baffle in the middle. The water enters through a pipe that goes all the way to the bottom of the sand and the water flows out from a simple elbow fitting glued into the top.Here is the sand filter under water in the sump. The pump is invisible at the bottom of the sump, below the filter socks. This helps draw water to the bottom of the sump.

I know it’s pretty impossible to tell what’s going on in that photo. The two flex hoses come from my 125 and 55 gallon tanks and they overflow directly into these big filter socks. The socks are just held in place with some zip ties and a piece of plastic tubing.

The three-quarter inch black tubing is poly propylene irrigation drip line. I used a little push on valve so I could control the flow and not blow excess sand into my filter sock. The smaller clear vinyl tube is the outflow from the sand filter and it goes into the left filter sock.

Having the entire system contained within the brute filter and completely underwater has other advantages besides containment of any drips.

Because there is no head pressure in the system anywhere when the pump is off, you do not have to worry about sand backing up into the pump should the system shut off. I turned it on and off several times and it starts right back up.

The other thing is that, should a hose pop off, the worst thing that can happen is that sand can wind up in the bottom of my Brute, And in the pump chamber filter sock.

If the hoses were external to the Brute, and one popped off at midnight, the system would blow 100 gallons of water out onto the ground before I woke up in the morning.

The sand I used was aragonite sand that I bought previously for my Cichlid tank, but I found that they like to dig it up way too much.

The two sand chambers are snack containers from the grocery store. It just so happens that the lids fit perfectly with a 4 inch sink strainer rubber washer and I used three of them to seal the system. There is a rubber washer between each cap and chamber and there was another rubber washer between the two caps which are back to back.

Those caps are clamped together inside by a 1.5 inch bulkhead fitting, which serves to baffle the chambers but still allow plenty of water flow. The blow tube is ordinary three-quarter inch drip irrigation pipe and I used epoxy putty to glue the roughened fittings into roughened holes in the PETE plastic snack containers.

I used Otey plumbers epoxy putty to hold the fittings. I have used this before on filters, but it tends to degrade after about five years under water. This may be due to something in the feed as I noticed it also turning a pink color, perhaps from the dye used in cheap fish food.

I know it will take a while for the sand to cycle in and although it is not brand new It has been out of the tank for months. Anyhow the system is running well I am hoping that it will improve things once it aGes. I did not take pictures of the construction, And I did not describe every part of it because I don’t attend this to be a how-to. I have tested the snack containers and they will take considerable pressure but the cap itself is the weak link.

One of these things could blow up in your face. They are strong but they don’t have the same quality control as a pressure vessel.

Last edited: