I have been the proud owner of an aquarium for over 8 years. I have been a cichlid owner since 2015. I am now getting ready to move my 70 gallon tank to a new custom built stand and add a sump. I have been searching the internet for the last few months and think I have finally settled on a design. I have finally understood how to avoid flooding my main tank and the sump in the event of power failures or blockages. I apologize if this has been posted in the past. I am hoping to get some input on the design so that i can start cutting the baffles and constructing the sump.

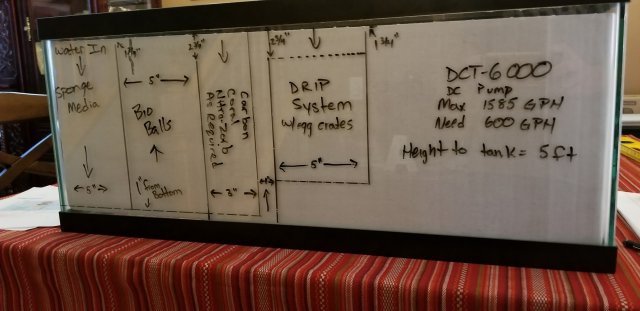

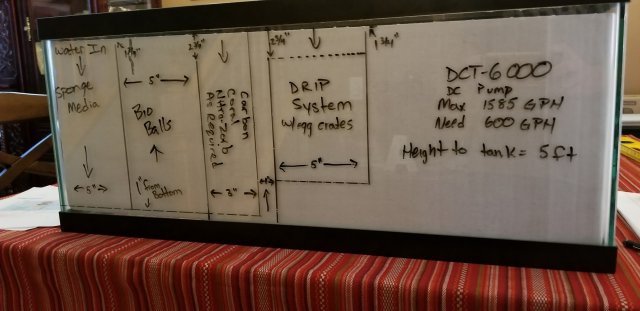

I apologize for the crude drawings as i have very little artistic skill, but I have wrote notes on the tank that will be used and don't have to worry about scale and all that high teck stuff with 3d drawing programs i can't understand. I have put what pump i plan on buying as it seems to allow flexible speeds easier and will provide more than needed for return flow which means i can upgrade in the future if needed.

The water comes in from the left and filters through the course sponge material to remove debris, then it flows from bottom up through the submerged bio-balls. It then flows down through the chemical filtration area (if needed) and runs through an empty baffle. Then the water is routed through the drip system and finally into the return chamber. The return chamber is 10.5 inches wide to allow the most space for it and hopefully avoid any evaporation issues or having the pump run dry or suck air.

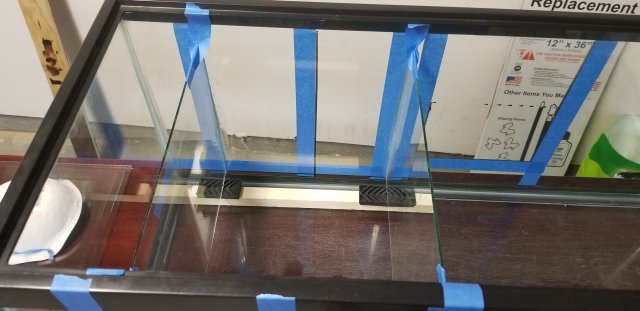

I have a 1 5/8' gap on the bottom of the first two chambers and again in the third chamber to try and keep the area clear of gunk. The top will have 1 5/8 inch gap to allow overflow if the bottom is blocked to prevent flooding. My tank and baffles are glass as that is what i have available for the project. Any input would be greatly appreciated.

I apologize for the crude drawings as i have very little artistic skill, but I have wrote notes on the tank that will be used and don't have to worry about scale and all that high teck stuff with 3d drawing programs i can't understand. I have put what pump i plan on buying as it seems to allow flexible speeds easier and will provide more than needed for return flow which means i can upgrade in the future if needed.

The water comes in from the left and filters through the course sponge material to remove debris, then it flows from bottom up through the submerged bio-balls. It then flows down through the chemical filtration area (if needed) and runs through an empty baffle. Then the water is routed through the drip system and finally into the return chamber. The return chamber is 10.5 inches wide to allow the most space for it and hopefully avoid any evaporation issues or having the pump run dry or suck air.

I have a 1 5/8' gap on the bottom of the first two chambers and again in the third chamber to try and keep the area clear of gunk. The top will have 1 5/8 inch gap to allow overflow if the bottom is blocked to prevent flooding. My tank and baffles are glass as that is what i have available for the project. Any input would be greatly appreciated.