turn two 3'x2'x2' acrylic tanks into one 3'x4'x4' acrylic tank is this possible

- Thread starter skillzizzo

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Im also a gemini... i get it ?... funny chit man... the mind dont stop unless you stop it by solving the problem. Maybe y i felt the need to reply just by ur verbage and questions ?? ... seems we really do think in a similiar way. I think i “have it tho” after reading some of your new thoughts. Do the setup like were talking about, on the actual stand (even better idea)... use anything u can to square it off properly... im thinking use the spacers to create and “set” the gap and also the ratchet straps or clamps to hold it all in place even flipping it one seam at a time. Spacers will make it all plumb/true and allow for the gap. Id honestly use small pieces of acrylic for spacers and just melt em right in... 40 is thick...it doesnt really “melt” like solvent... hence the need for sanding in some applications.

... seems we really do think in a similiar way. I think i “have it tho” after reading some of your new thoughts. Do the setup like were talking about, on the actual stand (even better idea)... use anything u can to square it off properly... im thinking use the spacers to create and “set” the gap and also the ratchet straps or clamps to hold it all in place even flipping it one seam at a time. Spacers will make it all plumb/true and allow for the gap. Id honestly use small pieces of acrylic for spacers and just melt em right in... 40 is thick...it doesnt really “melt” like solvent... hence the need for sanding in some applications.

U really want/need the gap for proper adhesion... its giving u more material in the joint to hold it together. The latter method of slapping er on top IMO will hold but not nearly as strong as the gap method. Itell give u more “bite”... i did think u could tie up the top tank engine hoist style, apply glue and just drop er down ?... however u “get there” the glue will hold if u get enough on and keep it there. Its runny but thick... y i suggest injection. It is self leveling to an extent but not for long as it sets up quick.

Also mentioned some of my old “mixes”/fillet sizes for tanks. I did everything overkill yrs ago. Was pouring 1/2-2” fillets on seams that prob would have held and been overkill enough at 1/4” fillets. The 40 is alot stronger than i realized at the time. Tend to suggest a bit less glue these days. Older...wiser... maybe just a bit more money conscience lol... the product is “overkill” in itself. If ur good with solvent its actually a very strong bond and would attach ur tanks together. Sheets can also be laminated with solvent but the chances of no bubbles and proper application are easier with the 40 i think.

Sorry to hear all ur gear was stolen ?... life always hits good people hard sometimes... gotta push forward as always... Not really a “fly guy”... i do chuck 12-14” hybrid flies for Esox certain times of year but exclusively make/sell big rubber baits and gliders for Pike and Musky... Hand carve all original designs then cast and mold them for production. I think u have Pike in AZ... invasive maybe but there i think haha... im “retired” from fish keeping due to unforeseen circumstances called life but spend about all my time now fishing for Esox or inventing new baits to target them... Same sickness as fish keeping really lol... im @CreekPikerLures on instagram if u wanna follow ?

U really want/need the gap for proper adhesion... its giving u more material in the joint to hold it together. The latter method of slapping er on top IMO will hold but not nearly as strong as the gap method. Itell give u more “bite”... i did think u could tie up the top tank engine hoist style, apply glue and just drop er down ?... however u “get there” the glue will hold if u get enough on and keep it there. Its runny but thick... y i suggest injection. It is self leveling to an extent but not for long as it sets up quick.

Also mentioned some of my old “mixes”/fillet sizes for tanks. I did everything overkill yrs ago. Was pouring 1/2-2” fillets on seams that prob would have held and been overkill enough at 1/4” fillets. The 40 is alot stronger than i realized at the time. Tend to suggest a bit less glue these days. Older...wiser... maybe just a bit more money conscience lol... the product is “overkill” in itself. If ur good with solvent its actually a very strong bond and would attach ur tanks together. Sheets can also be laminated with solvent but the chances of no bubbles and proper application are easier with the 40 i think.

Sorry to hear all ur gear was stolen ?... life always hits good people hard sometimes... gotta push forward as always... Not really a “fly guy”... i do chuck 12-14” hybrid flies for Esox certain times of year but exclusively make/sell big rubber baits and gliders for Pike and Musky... Hand carve all original designs then cast and mold them for production. I think u have Pike in AZ... invasive maybe but there i think haha... im “retired” from fish keeping due to unforeseen circumstances called life but spend about all my time now fishing for Esox or inventing new baits to target them... Same sickness as fish keeping really lol... im @CreekPikerLures on instagram if u wanna follow ?

Yup lol...IMO acrylic and wood are very similiar... even the small hand routers and cheap bits make quick work of it. Makes a mess but works well, heck even a dremel will buzz right through... i still use acrylic in my prototype work on baits almost daily.

.

.Its strong but has give...actually fairly soft...casts well for crazy shapes and im just comfortable with it. Dremel, sanding, router...multiple ways to cut it...still love it haha... This guy is headed to molding for soft plastic/rubber product... ????

all bits are not created equal though i bought a bosch i believe carbide blade last time and it was aw full in the router i had to make either 2 or 3 passes through quarter inch making baffle and was a crappy edge.

That is super cool man i never put much thought into how my rubber frogs are made for cutting small mouth with. Pike here I am not sure maybe up north. Where i am from i have caught northerns longer then winter sleds super fun. I have a frIend back home that owns a bait shop actually showed me how to pick them up right above there eyes on the notches they have and they sit perfectly still is pretty crazy. no musky any were were i am from. My absolute favorite fish to cetch, skin, cut up and eat are walleye. I do not eat much fish except them, catfish, and salmon, trout family, something about a big brown trout I go crazy for catching a 2 foot brown gets me pumped. I got to go trolling on lake ontario when i was a teenager just me my dad, my uncle, and cousin catching a big steel head jumping 10 feet out of the water was the best day by far of my life. I would love to see vids of you making stuff like that. jeffreybraley6965@gmail.com any time man hit me up

That is super cool man i never put much thought into how my rubber frogs are made for cutting small mouth with. Pike here I am not sure maybe up north. Where i am from i have caught northerns longer then winter sleds super fun. I have a frIend back home that owns a bait shop actually showed me how to pick them up right above there eyes on the notches they have and they sit perfectly still is pretty crazy. no musky any were were i am from. My absolute favorite fish to cetch, skin, cut up and eat are walleye. I do not eat much fish except them, catfish, and salmon, trout family, something about a big brown trout I go crazy for catching a 2 foot brown gets me pumped. I got to go trolling on lake ontario when i was a teenager just me my dad, my uncle, and cousin catching a big steel head jumping 10 feet out of the water was the best day by far of my life. I would love to see vids of you making stuff like that. jeffreybraley6965@gmail.com any time man hit me up

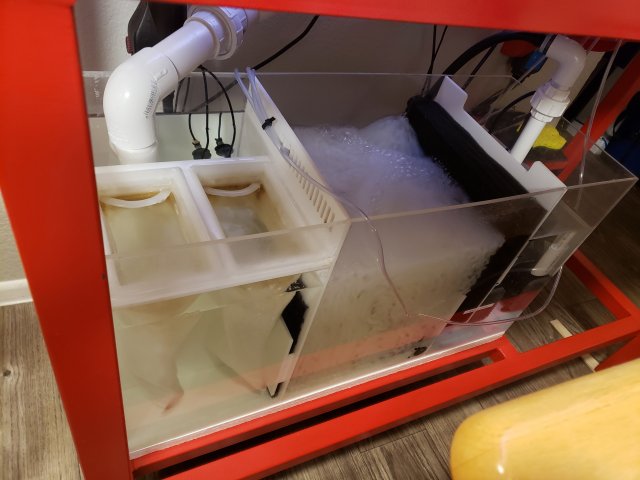

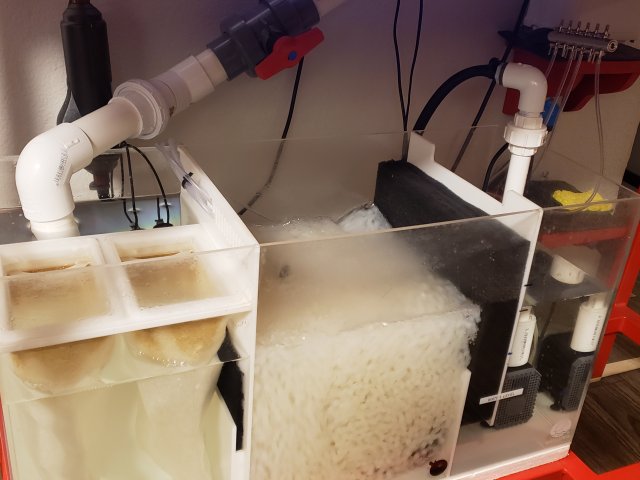

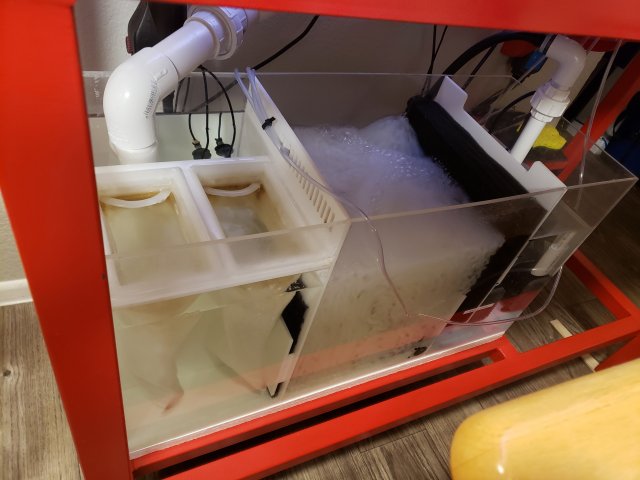

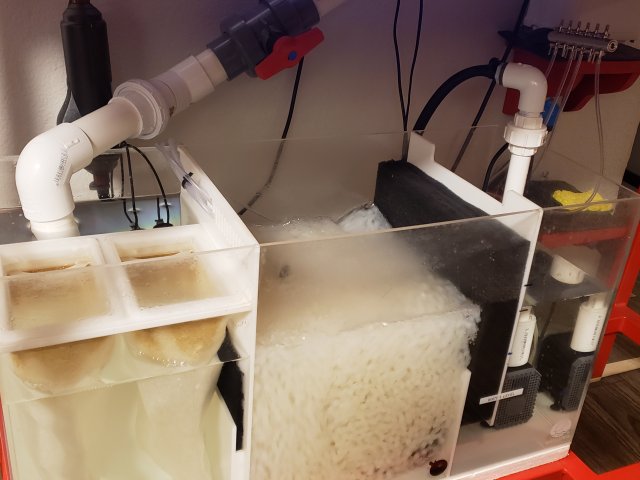

The gears in my head spin a very specific direction for sure. you say " use tiny pieces and just melt them in" I will have left overs from cutting out the holes but to make of a pain and possibly a finger trying to cut that small. Can gest some 1/4 or square stop and weld in some spacers with the #4 i got some some were but probably junk by now has been about 3 years since it last got use. good food for thought on double up acrylic to make a thick panel if you got a junk 180 or something 3 panels made into one will make a nice window for a big plywood build. i am not found of acrylic windows for those kind of build i would rather silicone in glass then bolt in acrylic seems the only way. I was reading in the #40 thread about it bonding acrylic to fiberglass projects so what exactly would work together in a coat my wood, and bond to my acrylic panel does highly interest me i will be building some kind of that style d.i.y tanks in my house for sure. I have never heard of an escox before. I really enjoy fishing well i did it sucks here. is a lot of small lakes you can just get out alone in your kayak, nothing over a trolling motor if that allowed catching trout all day, pesky yellow and white perk, small mouth large mouth, northerns and there cousins, grass pickerale some sun fish here and there just relaxing watching the steam in the morning of the pond is my type of thing. ya people steal **** and suck kind of had a run of bad luck in this state in the all most 2 years i have been here with some things but is all going well now. to bad for the loss of the aquarium hobby a lot of times is the only thing beside the good book that keeps my head from spinning around in a circle and every one going did you just see that I started checking out one of you metal frame builds got to did a little deeper into those when i have the time. I am working 5 to 6 days 1230 am to 12pm at the moment kind of why this tank is just in lets plan it properly stage. I have had that idea for about 5 years or so and have never actually seen it done. wondering if it is even cost effective to do the steel over wood. plus strenght you all ways think metal is strong but i actually just tore down a metal stand tank because the metal stand bows and tank does not sit flush and is 1.5 is square stock steel. the guy i had build it jacked it all up was supposed to have supports all over it. but i paid him first and got what i got really very unprofessional for some one who does it for a living. I could do it better in my sleep but i actually got rid of 99.5 percent of my tools before moving to a.z included my stick welder that was so old it was my dads, dads i beleive but damn sure will stick some stuff together for life. I did have a mig welder buy never learned how to get the feed, and tips, and wire type right honestly did not care im pretty good with a stick welder and at brazing stuff if it did not fit in my 12 x 6 trailer it got sold or got left behind and was not priority and had to think of wait issues as well pic included of said tank and stand i am refering to the blue from from the top of this post