Honestly I just considered the end to end bracing for the lid factor and figured that was why it was done like that before. You were absolutely right about the center needing to be beefed up and if I had done it like I originally planned the bracing would likely have been sagging an inch down in the water. Maybe I could take the 1 1/4 material that I have, notch down the ends and weld them across for side braces? I would think that would be enough support. I probably should have used it from the get go like you suggestedMore bracing can never hurt… the top takes the most pressure. Id bet if u capped the ends and maybe extended the width of the bracing there itd curb it. Could get away with less material running one across the center where u had ur clamps to the middle braces also tho just the same. Ive never worked with a 5’ width in all acrylic. I feel a bit responsible here as i told ya to change ur original bracing… you did need those centers beefed up tho like u got now lol…

600 gallon acrylic tear down and rebuild or roll the dice?

- Thread starter bluehand

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Honestly I just considered the end to end bracing for the lid factor and figured that was why it was done like that before. You were absolutely right about the center needing to be beefed up and if I had done it like I originally planned the bracing would likely have been sagging an inch down in the water. Maybe I could take the 1 1/4 material that I have, notch down the ends and weld them across for side braces? I would think that would be enough support. I probably should have used it from the get go like you suggested

Just noticed that original bracing/lip is inside the tank walls and not on top of it. Thats making the sides a bit odd to deal with. I know u got 1 piece of the 1/2” strip left. Id prob fill in the right side to make it flush at least. The left is a bit tougher with the section cracked out and patched underneath. Could get creative there and fill that gap then u could follow suit with another 1/2” strip to make the top all nice and flush.

Id might even do a 45/triangle piece over top all that with ur 1 1/4” to lock in all the panels/walls in the 4 corners. Overkill for sure. Ive never seen a top brace not capping the walls.

All just ideas, ur already there…The sides bother my brain not being flush

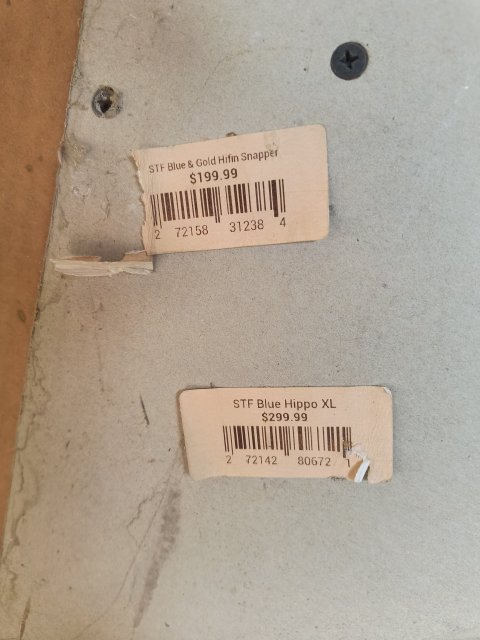

I agree that I should definitely cap the end panels. I was thinking maybe take a router and try to at least square that cracked side up a bit. It would have been so much easier to do before they patched it but cant change that now lol. Pretty sure all they cared about was keeping water in it. It was apparently at a fish store at some point, from the original pics you can see a row of these stickers all across the back side.Just noticed that original bracing/lip is inside the tank walls and not on top of it. Thats making the sides a bit odd to deal with. I know u got 1 piece of the 1/2” strip left. Id prob fill in the right side to make it flush at least. The left is a bit tougher with the section cracked out and patched underneath. Could get creative there and fill that gap then u could follow suit with another 1/2” strip to make the top all nice and flush.

Id might even do a 45/triangle piece over top all that with ur 1 1/4” to lock in all the panels/walls in the 4 corners. Overkill for sure. Ive never seen a top brace not capping the walls.

All just ideas, ur already there…The sides bother my brain not being flush… purely just aesthetics tho. Good thing is u still have material on hand to play with if u want too and shes holdin stong as is

…

The shop I got my bracing at is only like 10 minutes away from where I am currently working so to get a couple more strips if needed is not difficult. I was kinda thinking something along the lines of triangles in the corners a while back! How far would you think they should project out into the tank if I go that route?

Or maybe an 8' strip all the way across side to side while also capping the ends??? So many different options

Or maybe an 8' strip all the way across side to side while also capping the ends??? So many different options

Lol… i agree. The options are about endless. For the triangles in the corners. Theres really no wrong way to do it. If it were me and i had a certain material on hand. Id let that dictate how big i made them. Im usually working with alot of scraps and off cuts i get for $1 a pound at a local supply store.

I did have an idea to make those 2 center supports stronger. U can cut one of those 3-4” strips in half then glue them on top of the braces on end/vertically. That should stop any sagging at all. My only concern would b ur door jams and adding height to the tank. Could do the same with some strips of that 1 1/4” but thats alot of bulk to add on. If u did that id bet itd hold up ur side supports with how ur thinking of adding those on

Hahaha!! You are right inside my brain brother, that was actually another idea that I was considering with a standing seam to reinforce the bracing. Front door is 42" and the tank will be a straight shot about 10' inside so I think that would work wellLol… i agree. The options are about endless. For the triangles in the corners. Theres really no wrong way to do it. If it were me and i had a certain material on hand. Id let that dictate how big i made them. Im usually working with alot of scraps and off cuts i get for $1 a pound at a local supply store.

I did have an idea to make those 2 center supports stronger. U can cut one of those 3-4” strips in half then glue them on top of the braces on end/vertically. That should stop any sagging at all. My only concern would b ur door jams and adding height to the tank. Could do the same with some strips of that 1 1/4” but thats alot of bulk to add on. If u did that id bet itd hold up ur side supports with how ur thinking of adding those on

Hahaha!! You are right inside my brain brother, that was actually another idea that I was considering with a standing seam to reinforce the bracing. Front door is 42" and the tank will be a straight shot about 10' inside so I think that would work well

Ahh u got plenty room to get er in then with 42”… ive had to cut out a door jam before to get in a 32” height lol…

And nice… was hoping u understood what i was talking about. Id think even a 1”-1.5” height piece should suffice to give those braces a spine. Could probably even cut them, clamp em on and do a test to see if it sags with ur notched out/side pieces before u glue.