Had to come outta hiding for such an epic update from an O.G. of O.G.’s. ???... love it! Happy to see this man, great work...

1100 set up

- Thread starter Egon

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Reading this thread is epic, lots of good information to learn and a very detailed build thread to refer back to - a lot of ppl forget the KISS acronym, I’m glad you have made it a point to remember.

I think the biggest bonus was the comradery in the interactions with fellow mfkers, this is truly what this hobby is about.

Thank you for the time you have put into giving us an insight into your build ?

I think the biggest bonus was the comradery in the interactions with fellow mfkers, this is truly what this hobby is about.

Thank you for the time you have put into giving us an insight into your build ?

You are welcome, it’s truly my pleasure.Reading this thread is epic, lots of good information to learn and a very detailed build thread to refer back to - a lot of ppl forget the KISS acronym, I’m glad you have made it a point to remember.

I think the biggest bonus was the comradery in the interactions with fellow mfkers, this is truly what this hobby is about.

Thank you for the time you have put into giving us an insight into your build ?

My “safety” over flow pipe in my corner overflows of the tank just proved useful. I will try to explain with pictures.

History: I like to use every inch of gravity for filtration. If I’m spending my hard earned money to pump water up, then when it is coming back down, it will be filtered every inch of the way!

I love using overflows as bio towers. Depending on tank height you can get some significant bio towers in your system with out to much trouble. Just fill the overflows with bio balls. Your paying to pump the water up, might as well filter it all the way down!

On top of the corner filter “bio tower” I put a floss type mechanical filter. Super easy to access and change and, what the hell, another level of filtration. This filter easily clogs but works amazing. The more big chunks you pull out of your system the better. Unfortunately they clog easily and surprisingly fast especially over the holidays, why I’m posting now.

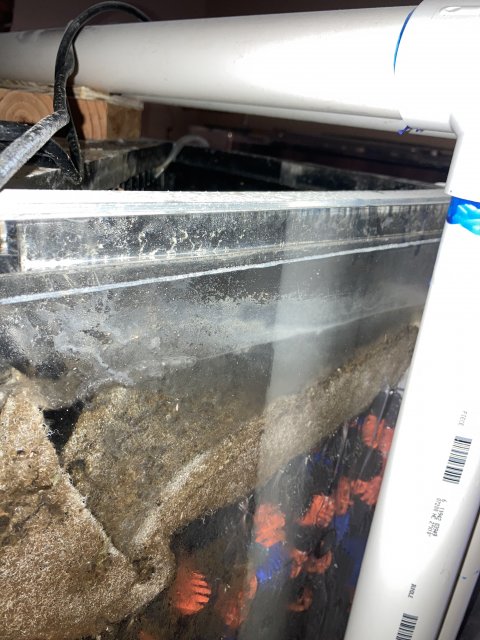

The left side corner over flow is fine. But the right side completely clogged up and the water level rose to the “safety”over flow pipe. If I didn’t install this pipe I would of overflowed the tank and water would of been pumped to the floor!

The pipe is in the back corner of the over flow so it’s out of the way and it’s just above the filter floss about an inch. If the floss gets clogged the water rises and then flows down this pipe to the sump bypassing the clogged floss and all the bio balls. Some reason this happens only over the holidays, Thanksgiving for example in my case. Thankfully this pipe worked and I don’t have a mess!!!!!

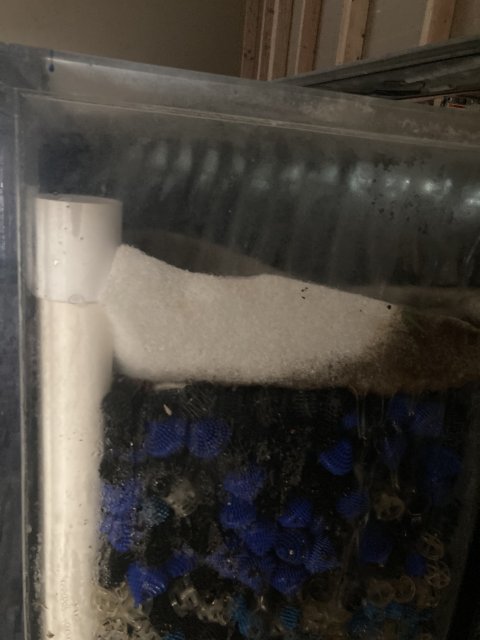

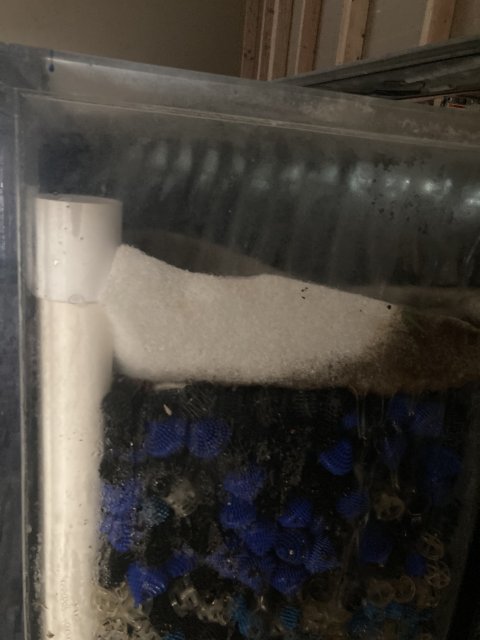

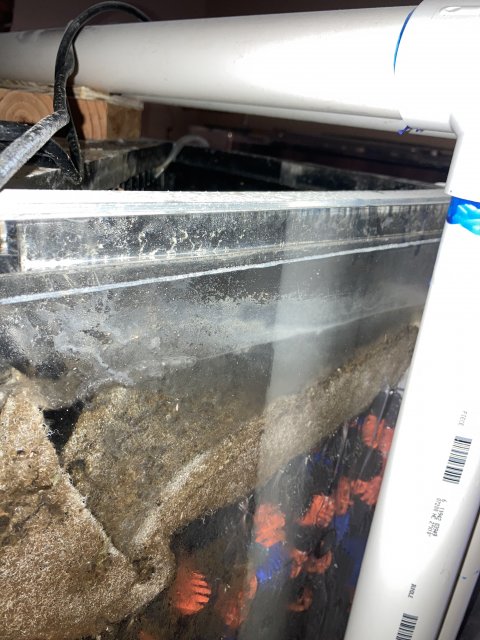

The attached two pictures are the good side. Normal running, not clogged. The white 2” pipe goes all the way down to the bottom of the overflow bypassing everything in the overflow

History: I like to use every inch of gravity for filtration. If I’m spending my hard earned money to pump water up, then when it is coming back down, it will be filtered every inch of the way!

I love using overflows as bio towers. Depending on tank height you can get some significant bio towers in your system with out to much trouble. Just fill the overflows with bio balls. Your paying to pump the water up, might as well filter it all the way down!

On top of the corner filter “bio tower” I put a floss type mechanical filter. Super easy to access and change and, what the hell, another level of filtration. This filter easily clogs but works amazing. The more big chunks you pull out of your system the better. Unfortunately they clog easily and surprisingly fast especially over the holidays, why I’m posting now.

The left side corner over flow is fine. But the right side completely clogged up and the water level rose to the “safety”over flow pipe. If I didn’t install this pipe I would of overflowed the tank and water would of been pumped to the floor!

The pipe is in the back corner of the over flow so it’s out of the way and it’s just above the filter floss about an inch. If the floss gets clogged the water rises and then flows down this pipe to the sump bypassing the clogged floss and all the bio balls. Some reason this happens only over the holidays, Thanksgiving for example in my case. Thankfully this pipe worked and I don’t have a mess!!!!!

The attached two pictures are the good side. Normal running, not clogged. The white 2” pipe goes all the way down to the bottom of the overflow bypassing everything in the overflow

Last edited:

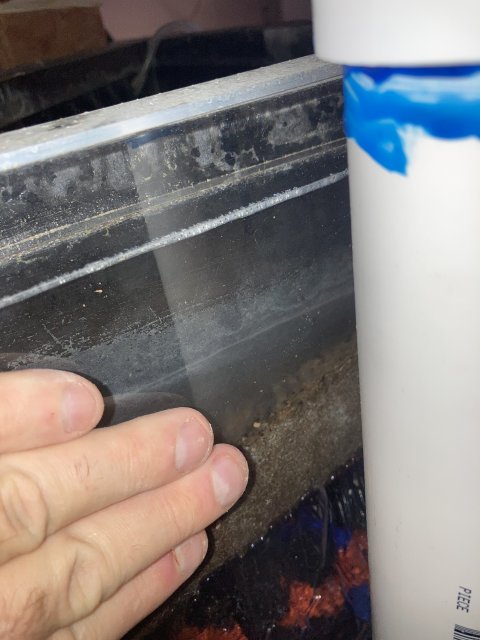

These three pictures you can see the water level is about an inch above the filter floss material and the water is going down the bypass.

I’ve learned the hard way and I’m passing this down to you guys. Very easy solution to a possible huge mess. Also allowing increased filtration for zero added energy cost. It’s surprisingly quiet also. Not as quiet as other systems but you get the added filtration benefit.

I’ve learned the hard way and I’m passing this down to you guys. Very easy solution to a possible huge mess. Also allowing increased filtration for zero added energy cost. It’s surprisingly quiet also. Not as quiet as other systems but you get the added filtration benefit.

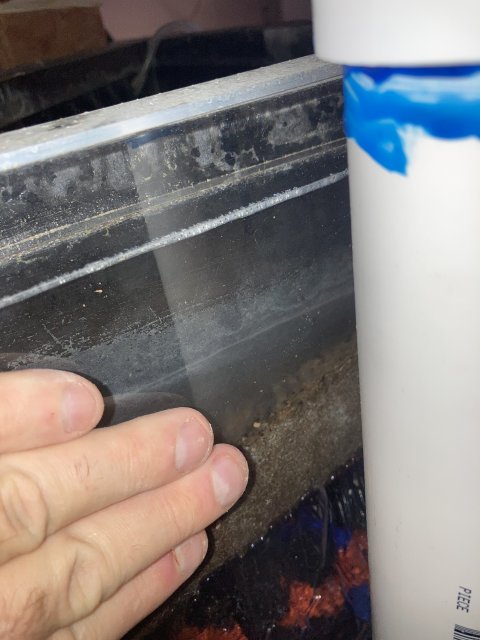

This pipe only goes to the bottom of the overflow. I explained earlier in this post how it’s set up If you want more detail. But the short version is I cut the bottom of the pipe at an angle so the pipe opening doesn’t accidentally seal to the bottom of the over flow restricting flow. Once the water gets to the bottom of the over flow it just flows out what ever holes you have down there. One hole or ten holes, it doesn’t matter. The point is getting past the clogged filter floss material at the top. Really the pipe only needs to be a couple inches long to do this, I just made it go all the way to the bottom to keep it from shifting/slipping/moving lower over time.That is a life saver! what if you only have 1 hole per overflow though?

Last edited: