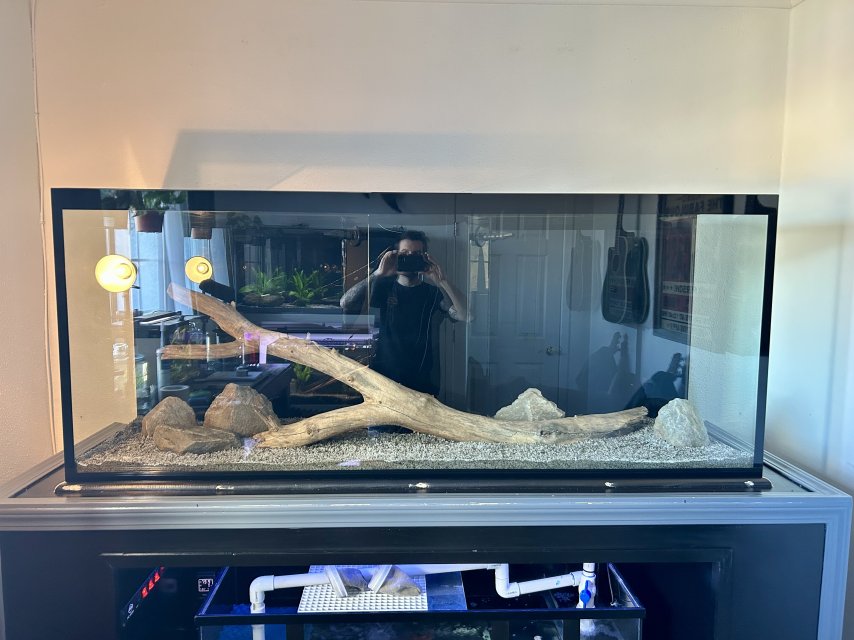

Not to beat a dead horse, but let's say I did a full true euro brace all the way around the inside perimeter of the tank with the option of a couple center cross braces if determined necessary. Obviously, this would mandate a revision of the weir to allow for access by either or both A. shortening it or B. making it stand off the back glass further to get out from under the brace enough for maintenance. Between that and the glass from the euro bracing my guess is I would be a lot closer to that 24" mark that we have been talking about. I haven't worked out the numbers yet but probably somewhere around a 26" water line is my guess. In your opinion would or should this fix my issues allowing me to confidently enjoy this tank or am I just clutching to dreams while wasting time and money?

It's gonna be considerable time, work, and money to do what you're suggesting.

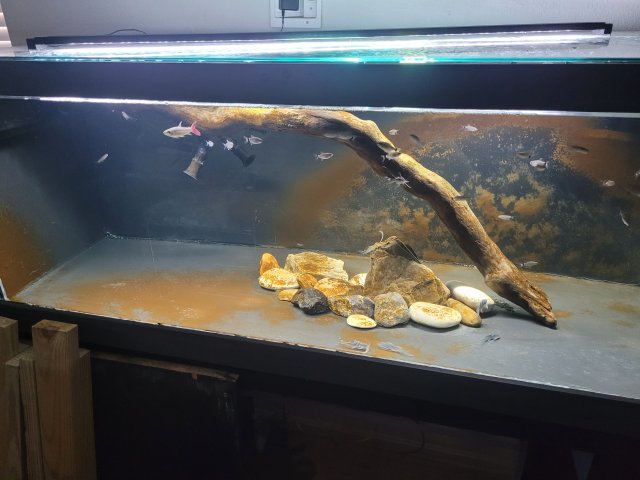

A few years ago I salvaged and scrapped a decades old red sea tank, removed the beautiful PPG Starphire panes, ordered 2x 63"x21"x3/8" tempered low iron panels but the eurobrace pieces I wanted would double the cost of the order--over budget for what was a sort of experimental project tank for me. So I rummaged my garage for scrap lumber and epoxy and came up with a rock solid epoxy coated, lag bolted lumber brace. This is the best pic I can find atm:

It's served me faithfully some three years now, now covered up under the deck for use as I might need it. Will the brace last forever? Idk....I couldn't even tell you what my safety factor is with all the different materials I used. A success nonetheless I say.

My point is: go ahead man. We can't tell you exactly what will work and won't. You seem like you have a knack and desire for DIY tanking and if/when you find some success youll probably want to build bigger and better next time with more hands on experience of what works and what doesnt.

All I can say is you probably shouldn't fill it over 24", but hey, if you want to experiment with a workaround I will not dissuade you any longer.

I will say one final time...if that plastic brace is gonna fit on your tank...too easy at $66+a tube of silicone.

.

.