Yes it was very much a typo in size, I am Looking to make one tank that is 3Lx4Dx2H

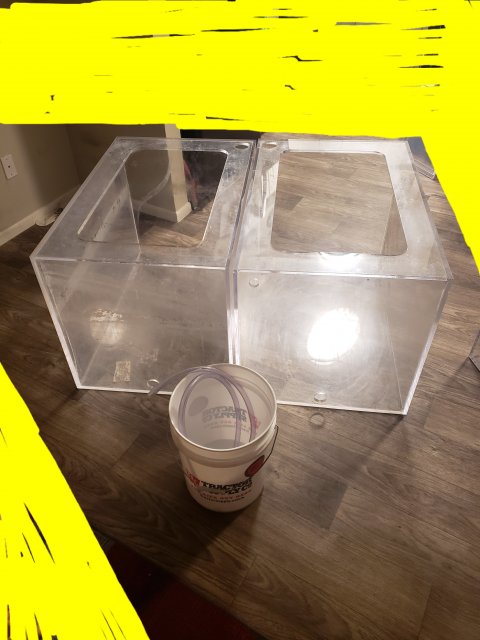

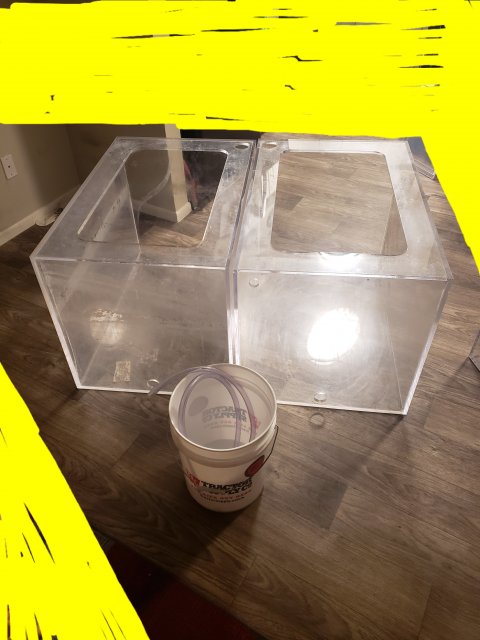

turn two 3'x2'x2' acrylic tanks into one 3'x4'x4' acrylic tank is this possible

- Thread starter skillzizzo

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

There is no way to cut 2 sides of exactly perfect by my hand so that would not be an option. I had a 180 a couple years ago that was cracked and i actualy did cut it all apart to make a smaller tank out of it. I tried a few ways one on table saw and another by skill saw and straight line jig neither way worked good enough for a perfect edge. And i am a highly skilled carpenter. I got it all rough cut then stored it. I i ended up giving the pieces to a freind when i moved from east coast to A.Z. i sadle got rid of all tanks and equipment i had at the time.

My actual idea here and only way that would realy make sence for me to do this is to join them as in back panel of one tank and front panel of the other tank. Leave the panels on the tank but make simple jig and run a router around the tank cut out the panel not of the panel. Leaving say and inch all the way around so about 1/2 inch extra because they are 1/2 acrylic. then use weldon 40 or another product to squeze in the out side seem and the indside seam.

or simply put the 2 tanks right up to each other back panel of one touch the front panel of the other used some kind of acrylic cement to bond them together alon top front and bottom out side seems. then cut out the wall from them with a router. then weldon the inside seem top, bottom, sides from the inside. problem with this way is you would not be able to get as close of a trim because the router would hit the wall.

the real quistion is would this be structual sound this way. I would not do it and put and acrylic strip all the way around the out side, then you would have to do the end on the bottom to level it. or adding full sheets to strenghten would just be a waste at that point better of to just build a new tank.

My actual idea here and only way that would realy make sence for me to do this is to join them as in back panel of one tank and front panel of the other tank. Leave the panels on the tank but make simple jig and run a router around the tank cut out the panel not of the panel. Leaving say and inch all the way around so about 1/2 inch extra because they are 1/2 acrylic. then use weldon 40 or another product to squeze in the out side seem and the indside seam.

or simply put the 2 tanks right up to each other back panel of one touch the front panel of the other used some kind of acrylic cement to bond them together alon top front and bottom out side seems. then cut out the wall from them with a router. then weldon the inside seem top, bottom, sides from the inside. problem with this way is you would not be able to get as close of a trim because the router would hit the wall.

the real quistion is would this be structual sound this way. I would not do it and put and acrylic strip all the way around the out side, then you would have to do the end on the bottom to level it. or adding full sheets to strenghten would just be a waste at that point better of to just build a new tank.

Put em on the same stand...run 1 sump... those r much too nice to chop up IMO... ur idea of routering out holes and joining them that way is ur best option if u do choose to chop em... ud only need to glue the 2 lips together no need for anything on the outside or even extra bracing with 1/2” material and a 1-2” lip of material for joining.

Hello i was actualy thinking of contacting you but did not want to bother you. I work third shift and had last night of and actually read every single word i believe was 24 pages in your sticky for weldon 40 tip poor fun. after reading it i was surely wondering the best way to approach this idea using weldon 40. I have never actualy used the product. other cements yes to build a couple small tanks to practice for the above mentioned 180 i cut up. and to build baffles and so forth for sumps.

what do you feel would be the best approach at joining these with weldon 40 is what i am assuming the product you were refering to using to do the job. Do you think cut out the router hole on both tanks 2 inches around be enough. Sand both ends with 400 grit? and as simple as mix up weldon 40 brush on the seem of one and set the other on top of it making sure it is perfectly square on it? then good to Go? would it really be that simple because i have a router for the job , just need the right bit. You can all so get a flush cut bit the will literally run right along the inside grove making it the same as you cut the end of but I like the idea of leaving the 1 to 2 inch meat for bite and it will give the middle of the tank more strenght the cutting it all out. if you did it this way how much #40 as in how thick would you do is going to smoosh out of it. Then the question is would you tighten in town with something like a ratchet strap or just let gravity do the work. I know you know what you are talking about so trust what you say on this product. if it is realy this simple with out extra supports and so forth i will surely be doing it.

Yes you are right they are pretty sweet size tank dimension of a 120 but a foot shorter little stubby tank or a 180 cut in half or a wide 65 gallon i do have a soft spot for 65 gallon tanks. I could turn it into a standard 180 but why bother there not hard to come by. i have thought of doing the same thing as i am saying here but not cut out sides just join as is and drill hole in then and a slot in the bottom to slide a pot base through for breeding purposes. but realy the most usefull to me is a 3L x 4D x 2 high would be a great little indoor pond type tank. i have allways wanted a 4x4 or 3x5 kind of size tank just for fun and this is the only real chance im going to have because when it comes down to hard earn money spend on a new build i wont be doing these demension. Options are endless is a great hospital tank for large fish. I wont be keeping 20" fish in it for life but they surely can hang out to heal up. some of the seems have crazing in them and air bubbles so i will be weldon tip menthod of them so now is the time if i am going to do it. Then buff it out and fill it up. Honestly i just need prodjucts in life to keep my mind going and this is a fun size tank to me and very usable

what do you feel would be the best approach at joining these with weldon 40 is what i am assuming the product you were refering to using to do the job. Do you think cut out the router hole on both tanks 2 inches around be enough. Sand both ends with 400 grit? and as simple as mix up weldon 40 brush on the seem of one and set the other on top of it making sure it is perfectly square on it? then good to Go? would it really be that simple because i have a router for the job , just need the right bit. You can all so get a flush cut bit the will literally run right along the inside grove making it the same as you cut the end of but I like the idea of leaving the 1 to 2 inch meat for bite and it will give the middle of the tank more strenght the cutting it all out. if you did it this way how much #40 as in how thick would you do is going to smoosh out of it. Then the question is would you tighten in town with something like a ratchet strap or just let gravity do the work. I know you know what you are talking about so trust what you say on this product. if it is realy this simple with out extra supports and so forth i will surely be doing it.

Yes you are right they are pretty sweet size tank dimension of a 120 but a foot shorter little stubby tank or a 180 cut in half or a wide 65 gallon i do have a soft spot for 65 gallon tanks. I could turn it into a standard 180 but why bother there not hard to come by. i have thought of doing the same thing as i am saying here but not cut out sides just join as is and drill hole in then and a slot in the bottom to slide a pot base through for breeding purposes. but realy the most usefull to me is a 3L x 4D x 2 high would be a great little indoor pond type tank. i have allways wanted a 4x4 or 3x5 kind of size tank just for fun and this is the only real chance im going to have because when it comes down to hard earn money spend on a new build i wont be doing these demension. Options are endless is a great hospital tank for large fish. I wont be keeping 20" fish in it for life but they surely can hang out to heal up. some of the seems have crazing in them and air bubbles so i will be weldon tip menthod of them so now is the time if i am going to do it. Then buff it out and fill it up. Honestly i just need prodjucts in life to keep my mind going and this is a fun size tank to me and very usable

Hello i was actualy thinking of contacting you but did not want to bother you. I work third shift and had last night of and actually read every single word i believe was 24 pages in your sticky for weldon 40 tip poor fun. after reading it i was surely wondering the best way to approach this idea using weldon 40. I have never actualy used the product. other cements yes to build a couple small tanks to practice for the above mentioned 180 i cut up. and to build baffles and so forth for sumps.

what do you feel would be the best approach at joining these with weldon 40 is what i am assuming the product you were refering to using to do the job. Do you think cut out the router hole on both tanks 2 inches around be enough. Sand both ends with 400 grit? and as simple as mix up weldon 40 brush on the seem of one and set the other on top of it making sure it is perfectly square on it? then good to Go? would it really be that simple because i have a router for the job , just need the right bit. You can all so get a flush cut bit the will literally run right along the inside grove making it the same as you cut the end of but I like the idea of leaving the 1 to 2 inch meat for bite and it will give the middle of the tank more strenght the cutting it all out. if you did it this way how much #40 as in how thick would you do is going to smoosh out of it. Then the question is would you tighten in town with something like a ratchet strap or just let gravity do the work. I know you know what you are talking about so trust what you say on this product. if it is realy this simple with out extra supports and so forth i will surely be doing it.

Yes you are right they are pretty sweet size tank dimension of a 120 but a foot shorter little stubby tank or a 180 cut in half or a wide 65 gallon i do have a soft spot for 65 gallon tanks. I could turn it into a standard 180 but why bother there not hard to come by. i have thought of doing the same thing as i am saying here but not cut out sides just join as is and drill hole in then and a slot in the bottom to slide a pot base through for breeding purposes. but realy the most usefull to me is a 3L x 4D x 2 high would be a great little indoor pond type tank. i have allways wanted a 4x4 or 3x5 kind of size tank just for fun and this is the only real chance im going to have because when it comes down to hard earn money spend on a new build i wont be doing these demension. Options are endless is a great hospital tank for large fish. I wont be keeping 20" fish in it for life but they surely can hang out to heal up. some of the seems have crazing in them and air bubbles so i will be weldon tip menthod of them so now is the time if i am going to do it. Then buff it out and fill it up. Honestly i just need prodjucts in life to keep my mind going and this is a fun size tank to me and very usable

1st off...cant believe u read every word of my sticky haha ??... i am glad to see my info is still being used tho. Was alot of just trial and error on my part yrs ago. Sounds like uve “got ur feet wet” enough with cement/solvent /cutting to dive right into using #40. If u can buff already also thats basically all the skill set u need to put out a “factory” product. Most of it is just patience, time...and the desire to do it. Anything is really possible with acrylic new or old. Think of #40 like bondo for a car but much much stronger. The chemical components are almost exactly the same as the acrylic itself. If u can mix 2 part epoxy u can use #40 no prob. Id wager u only need a pint kit maaaaybe 2 if u want to do some other work on the tanks that would run you around $60-75. I think the pint kits are still around $35.

It really is as easy as just dumping some around one tank “rim” uve routered and pretty much placing the other tank on top then let er set up... the hard part is keeping it clean as any glue that spills or gets on an area u dont want is not easy to get off once hard. No other way than routering, cutting or sanding it back down smooth so u gotta kinda plan ur steps carefully before u mix/apply. If u can “buff” including sanding ull b fine for any “clean up”...

Ratchet straps/pressure are not needed like with solvents. U actually want it to be “loose” and not squeeze the glue out. The gravity alone will be plenty, u may even want to place some small 1/8” pieces/spacers of acrylic down just to prevent the glue from oozing out. U can trap the glue in with masking tape. It is plenty strong enough to go down to just the material thickness for a bond. They bond panels together all the time in tank construction over 8’. 2” rim like were talking about would b extreme overkill IMO...1/2”- 1” will be plenty. If ur feelin game, go for it with the flush bit even lol... if ur good at sanding:buffing u can make it look like the seam is about gone all together.

The “correct” way to join 2 panels together is to actually leave a 1/8-1/4” gap then fill it in with the #40. Unlike silicone 40 will adhere to itself very well. So if u plan out how to join u can do 1 side of the tank at a time to keep it clean. “Slapping” one tank on the other will work but ull pay for it in clean up/looks.

If i were to do it id get the tanks set up in place with a 1/8”-1/4” gap, run a piece of masking tape on the underside of the tank/seam im working on and inject the 40 into the gap. Prob do 1 seam at a time, let it harden for a day, flip to a new side/seam then repeat. The tape pulls right off the dried 40 clean. Packing tape works well also, its harder to get off as it tears but its stronger.

If uve read my rants already lol...u know 40 is like a thick syrup. It can be applied in syringe type applicators if u cut the tips bigger, cheap ketchup/mustard bottles with a tip or even packed into empty silicone tubes for injection. As lame as it sounds the show “tanked” actually joined a panel together on the show using the silicone tube/chaulk gun filled with pre mixed 40 with a piece of tape along the back seam. As the guy injected he ran a piece of tape up vertically on the side he injected from if u understand what im sayin. Pretty cool honestly. Ud only need to tape the back/bottom and a bit on the ends if u do 1 seam at a time flat on a table.

Keep in mind u only have 15/30min depending on tempature/ 40 volume/ “pot size” to work so it really is smart not to try and do the whole thing at once. Ull waste less glue and ull get good at measuring/mixing it. Smaller glue amounts take longer to start curing than larger amounts. I mixed a bit over a pint at once before lol... it heated up so quick by the time i got it in my squeeze bottle it burnt my hands ??... Dont mess around haha, have a step planned and setup before u mix...Also whatever “applicator” ur using is pretty much toast after each use also. 4 seams, get 4 applicators. The empty chaulk tubes are cheap, or any kind of squeeze bottle also.

If u understand what im explaining with injection it really is easy. Itell take more time to cut/prep the tank but the flush bit/material thickness will be the easiest to “inject” and come out the cleanest in the end and use the least amt of glue to save $$. If u take er down that far id use the reg style plunger tubes/syringe 1” diamater or so for application. There sold for medicine or rinsing ur teeth sometimes after a surgery. Prob on amazon these days. If u set everything up before hand the 1st seam/injection will take the longest prep. After that the 3 remaining sides will b a breeze as the tank will already b attached to itself with a set gap to just tape off and inject the rest. Id still prob do em 1 at a time just to work flat and be careful not to crack the 1st injection.

Hope my “rant” helps ?... its been a while lol... but u seem like ur determined and capable to make it happen more so than the “average” please help msg... or someone who dosent listen ??... kinda got tired of helping people a bit who would do something opposite i suggested then wonder y things went south lol... ??

First off thank you for taking the time for such a detailed reply. And yes I really did read the hole sticky, and it is still very viable, relevant, and usable information. In fact it is the only place on the web to find that information. I have looked all over the web and find nothing on weld on #40 no real vids on how to use it, when to use it, what purpose it is really made for nothing it is super crazy. would be an equivalent to looking for a how to patch fiberglass search and finding no information on resin. No were on any thing i have ever read or watched about any acrylic tank making have i seen any thing about it and i have watch many hours of vids on the subject in my life time. I am very thank full you made that article not just in the case of this project but having to do with any thing acrylic.

After reading your reply i am left thinking about which way makes most since to do this. both ways mentioned have some pros and cons. I think really the final answer on how to do it is determined buy what will make the best for life joint, or bond. Is there really going to be a difference in the actually bond in the end is the question now to be answered? In theory both bonds regards of if it has a 1/8th to 1/4 gap or simply applied to both sides and put together will result in the same strength bond wont they? because really what is happening is the new #40 is melting the old acrylic and bonding them together correct. So what is the real purpose of doing it to leave the gap and then put the #40 in the gap? is it simply to make sure there are no air pockets or voids left in the material its self? which will result in a better long term bond? is it self leveling and self filling to avoid voids, and gaps when done with the space method i know it gets air bubbles that is not what i am referring to here.

Both ideas present a different set of challenges to actually do them. The method of applying the #40 and sticking them together is going to be challenging for a few reason one being after applying the #40 to the joint you have to rush and put the other tank on top of the bottom one. There is no way to have them in place before you start the process. And i see it being a real pain to do i just set them up in my house this way and was not easy to get lined up and will be even more of a challenge with a slippery substance in between them. Plus the more you have to move it once on top the more it is going to move the #40 around making it leave the seem and go all over were it is not supposed to be. I do not much care if it gets on the tank because my front panel will be facing up. and it can be sanded, polished, buffed so forth and both sides and back will be red and the bottom will be black so only panel that matters is the front but i do still want the best joint by not having a lot of the #40 either smoosh out or gets pushed out. after really thinking all this and typing all this this method really seems like a bad idea on trying to do it this way.

The way you mentioned with the 1/8th to 1/4 inch gap one pro over other method would be the be able to have it all set up and ready to go not worrying about rushing to deal with that part once #40 is mixed up. the hard part is going to be to get the spacing right for it. you can get the spacing multiple ways with say tile grout spacers. but the problem is going to be not getting one space right for say the bottom of the tank but all at the same time because it does need to be flat and square at the end of the process. the only way i am able to see this in my head currently is to build the actual stand first so you have a level surfice to work on. Alteast it will be molded to where it will actually be sitting. Leave the bottom gap open, space both sides, and the top. then strap it lightly to hold in exact position. Poor the bottom seem, then flip and rotate as you said one seem at a time. still trying to figure this part out. i am surely going to do it this way thow with a gap still leaving any were from 3/4 to and inch of a lip to leave 1/4 to half inch over hang after subtracting the 1/2" thick tank just to simply have a thick wall to really fill full of the #40 for my own piece of mind. I noticed in the right up some one says using something that vibrates near the mixture while waiting 3 minutes after mixing it to remove air bubbles. not sure how to do this to the actual tank but might help it go down evenly into the deep crack and settle evenly with no air bubbles any thoughts on that? in my head there Is a few problems to work out with the process but i do feel though the gap method will yield the best final result. Thoughts? concerns?

It is good to note what you said about the more you mix the hotter it gets and less time you have to work with it. I must say this product bonding to its self, and being able to do one seem at a time is great. Over say silicone that sucks badly that is does not stick to its self and you better get it done in one shot and right in one shot or you are doing a lot of work to get it all back off again just to repeat. it is nice to test and have a little leak and be able to reapply more then have to redo the hole project for sure

I was taking notes when i read the #40 thread of all mentioned amounts lets see what i got. 1 pint 40 -50 gallon all seems, 8x2x2 done with 3 quarts all seems 1/2 thick poor most important ratio 200ml to 10ml for 1 x 8 foot seem. which i have learned from making my own E liquid 1 ml equals 1 ounce on a scale and I have 2 different very accurate scales for making e liquid. Some other use full info was the warmer it it the better the seems come out which is good because i live in A.Z were it is never cold one go showed seems at 82 degrees and were really good, all so lower humid equals longer set up +, can fill up to 1/4 gap with #40, u have used on raw ends right of table saw, all so I saw it mention higher temps thin it out is there a different ratio to mix for actual temp on the can? 15 to 30 min cure time, 72 hrs to full cure.

You are right in I am determined person once i get an idea in my head I sadly can not remove it until it is done. Well it was just and idea and I was not sure what I was doing with these tanks was just to good of a deal to pass on them I bought a few hours after finding them and the other 54L x 24W x 14H tank pictured the blue one I all ready had Hence this thread started and I am glad you chimed in on it. I am now sure it is not a waste of two good tanks but a very good plan on how to do it. I had all ready planned on doing the seams any ways so really is not much more work involved here. And I surely did read the info you put out. I am some one plans every thing out, and gets as much info as I can on it before hand I used to do as I go gemini mind set and never a good idea. when some one takes the time to give me proper advise I like to use that knowledge not waste it.

Your a bait maker? You mean Fly maker? I am an avid fisherman my self. Well I was until I moved to this desert called Arizona nothing but crappy man made lakes here made by flooding the river system. At least in the part I live in. I am from N.H were I used to literally open my map book for work and find new ponds and lakes weekly to go I had never been. Is water damn near every where. Sadly on Easter of 2020 while I was working I had my 12x6 enclosed trailer broken into and mine, and girl friends kayaks were stolen, all my fishing gear, My Harley, and a bunch of my tools. scumbags even stole my totes with my Christmas stuff in it. got to love meth right.

Any ways thanks for the reply I do appreciate you time here as well in the original #40 -42 right up. It is going to be awhile before this project gets started. Me and my long time girl friend are having a house built now will be done by the end of the year and probably not gotten to till then. I have to do the other two tanks pictured first I had the blue one set up solo with a sump, and ripped it down to build together with the one on top of it. the fish from it are in some smaller holding tanks at the moment so sadly that is more of a priority currently. which will be another thread in its self. When I get ready to do this I will surely be either updated this or making a new threads completely either way I will tag you in it so you can check it out maybe have some more questions or feed back by then thanks for your time I appreciate I was mainly looking now to see if that was even possible so I could stop thinking about it a million ways in my head you helped a lot I think I got it covered for the most part now

After reading your reply i am left thinking about which way makes most since to do this. both ways mentioned have some pros and cons. I think really the final answer on how to do it is determined buy what will make the best for life joint, or bond. Is there really going to be a difference in the actually bond in the end is the question now to be answered? In theory both bonds regards of if it has a 1/8th to 1/4 gap or simply applied to both sides and put together will result in the same strength bond wont they? because really what is happening is the new #40 is melting the old acrylic and bonding them together correct. So what is the real purpose of doing it to leave the gap and then put the #40 in the gap? is it simply to make sure there are no air pockets or voids left in the material its self? which will result in a better long term bond? is it self leveling and self filling to avoid voids, and gaps when done with the space method i know it gets air bubbles that is not what i am referring to here.

Both ideas present a different set of challenges to actually do them. The method of applying the #40 and sticking them together is going to be challenging for a few reason one being after applying the #40 to the joint you have to rush and put the other tank on top of the bottom one. There is no way to have them in place before you start the process. And i see it being a real pain to do i just set them up in my house this way and was not easy to get lined up and will be even more of a challenge with a slippery substance in between them. Plus the more you have to move it once on top the more it is going to move the #40 around making it leave the seem and go all over were it is not supposed to be. I do not much care if it gets on the tank because my front panel will be facing up. and it can be sanded, polished, buffed so forth and both sides and back will be red and the bottom will be black so only panel that matters is the front but i do still want the best joint by not having a lot of the #40 either smoosh out or gets pushed out. after really thinking all this and typing all this this method really seems like a bad idea on trying to do it this way.

The way you mentioned with the 1/8th to 1/4 inch gap one pro over other method would be the be able to have it all set up and ready to go not worrying about rushing to deal with that part once #40 is mixed up. the hard part is going to be to get the spacing right for it. you can get the spacing multiple ways with say tile grout spacers. but the problem is going to be not getting one space right for say the bottom of the tank but all at the same time because it does need to be flat and square at the end of the process. the only way i am able to see this in my head currently is to build the actual stand first so you have a level surfice to work on. Alteast it will be molded to where it will actually be sitting. Leave the bottom gap open, space both sides, and the top. then strap it lightly to hold in exact position. Poor the bottom seem, then flip and rotate as you said one seem at a time. still trying to figure this part out. i am surely going to do it this way thow with a gap still leaving any were from 3/4 to and inch of a lip to leave 1/4 to half inch over hang after subtracting the 1/2" thick tank just to simply have a thick wall to really fill full of the #40 for my own piece of mind. I noticed in the right up some one says using something that vibrates near the mixture while waiting 3 minutes after mixing it to remove air bubbles. not sure how to do this to the actual tank but might help it go down evenly into the deep crack and settle evenly with no air bubbles any thoughts on that? in my head there Is a few problems to work out with the process but i do feel though the gap method will yield the best final result. Thoughts? concerns?

It is good to note what you said about the more you mix the hotter it gets and less time you have to work with it. I must say this product bonding to its self, and being able to do one seem at a time is great. Over say silicone that sucks badly that is does not stick to its self and you better get it done in one shot and right in one shot or you are doing a lot of work to get it all back off again just to repeat. it is nice to test and have a little leak and be able to reapply more then have to redo the hole project for sure

I was taking notes when i read the #40 thread of all mentioned amounts lets see what i got. 1 pint 40 -50 gallon all seems, 8x2x2 done with 3 quarts all seems 1/2 thick poor most important ratio 200ml to 10ml for 1 x 8 foot seem. which i have learned from making my own E liquid 1 ml equals 1 ounce on a scale and I have 2 different very accurate scales for making e liquid. Some other use full info was the warmer it it the better the seems come out which is good because i live in A.Z were it is never cold one go showed seems at 82 degrees and were really good, all so lower humid equals longer set up +, can fill up to 1/4 gap with #40, u have used on raw ends right of table saw, all so I saw it mention higher temps thin it out is there a different ratio to mix for actual temp on the can? 15 to 30 min cure time, 72 hrs to full cure.

You are right in I am determined person once i get an idea in my head I sadly can not remove it until it is done. Well it was just and idea and I was not sure what I was doing with these tanks was just to good of a deal to pass on them I bought a few hours after finding them and the other 54L x 24W x 14H tank pictured the blue one I all ready had Hence this thread started and I am glad you chimed in on it. I am now sure it is not a waste of two good tanks but a very good plan on how to do it. I had all ready planned on doing the seams any ways so really is not much more work involved here. And I surely did read the info you put out. I am some one plans every thing out, and gets as much info as I can on it before hand I used to do as I go gemini mind set and never a good idea. when some one takes the time to give me proper advise I like to use that knowledge not waste it.

Your a bait maker? You mean Fly maker? I am an avid fisherman my self. Well I was until I moved to this desert called Arizona nothing but crappy man made lakes here made by flooding the river system. At least in the part I live in. I am from N.H were I used to literally open my map book for work and find new ponds and lakes weekly to go I had never been. Is water damn near every where. Sadly on Easter of 2020 while I was working I had my 12x6 enclosed trailer broken into and mine, and girl friends kayaks were stolen, all my fishing gear, My Harley, and a bunch of my tools. scumbags even stole my totes with my Christmas stuff in it. got to love meth right.

Any ways thanks for the reply I do appreciate you time here as well in the original #40 -42 right up. It is going to be awhile before this project gets started. Me and my long time girl friend are having a house built now will be done by the end of the year and probably not gotten to till then. I have to do the other two tanks pictured first I had the blue one set up solo with a sump, and ripped it down to build together with the one on top of it. the fish from it are in some smaller holding tanks at the moment so sadly that is more of a priority currently. which will be another thread in its self. When I get ready to do this I will surely be either updated this or making a new threads completely either way I will tag you in it so you can check it out maybe have some more questions or feed back by then thanks for your time I appreciate I was mainly looking now to see if that was even possible so I could stop thinking about it a million ways in my head you helped a lot I think I got it covered for the most part now

in final production one of the 3' sides will be the front viewing panel, the 2 joined 2' side to make a 4' section will be the sides. one tank is a mm or 2 longer and higher then the other, but the bottom panel lines up all most perfect is all that really is going to matter in the end as far as joining them goes

This is what i will be using to either flush cut the sides off with or leave an edge just simply put a spacer to desired depth inside the seem of the tank. But with a hand router not a table

12vtools.com

12vtools.com

SFT.500 1/2" Shear Angle Flush Trim Router Bit - 12vTools.com

Shear angle Flush Trim bit Great for MDF, Birch, Plastics and Aluminum 1" cut length 1/2" diameter 1/2" or 1/4" shank