How long should I let the first seam sit before rolling the tank to do the next?

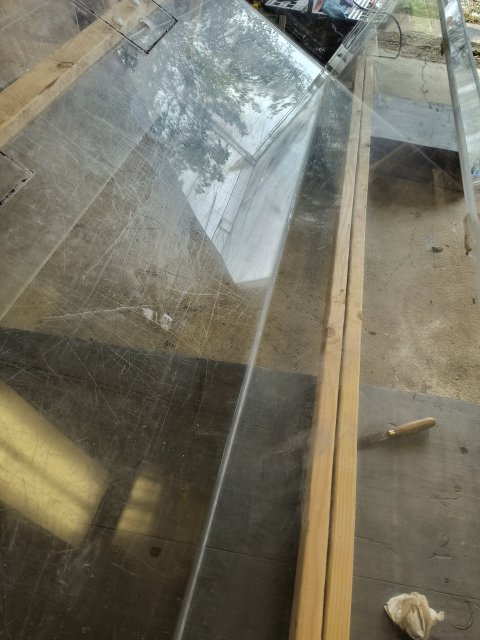

Once it sets up ur safe to move the tank, so usually around and hour. like regular welding its best to jump around to spread the heat of the glue curing. 3/4” material takes the heat fairly well. If you go too quick between pours or work right next to where u just did it will cause crazing (spider web/shattered glass looking scratches) crazing from this is not damaging in any way other than looks. Only way to cure it is in a giant oven tho.

Ive gone as quick as 45min to an hour between pours and used up to a gallon just straight through all day on 1 tank. I do not recommend that tho unless in an emergency.

2-3 hours is pretty safe between pours. Each tank is different tho also. Go by feel, if the material is still warm wait till it cools down before pouring by it again. Full cure on a pour is 48 hrs but you wont hurt anything moving the tank or working after its initially set up.