Decisions made.

- Thread starter FINWIN

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Just to clarify, I realize that those fragile plastic monsters need full bottom support. All I meant was that you can use a solid top made of perhaps a couple of stacked pieces of plywood to provide that. You can even have a cross-shaped brace underneath, formed from pieces of 2x4 or even 2x6 attached vertically to the bottom of the lowest sheet in the stack. They would run front to back and side to side, sitting between the columns of concrete at each corner. A construction like that absolutely will not allow any flexing, and that's all that "full support" means.

You could even have the columns set 1.5 or 2 inches inside the perimeter of the top, and then run a another vertical brace all around the outside edge, wrapping around the top of the concrete blocks. This would make it simple to attach curtains (fabric or solid) to the bottom of those braces to hide the structure, but which will still be quick and easy to remove for service, etc.

I know you want to take no chances, but...do some research on this. It will work.

wednesday13

wednesday13

Backfromthedead

Backfromthedead

Fishman Dave

M

M1A1

Fishman Dave

M

M1A1

You could even have the columns set 1.5 or 2 inches inside the perimeter of the top, and then run a another vertical brace all around the outside edge, wrapping around the top of the concrete blocks. This would make it simple to attach curtains (fabric or solid) to the bottom of those braces to hide the structure, but which will still be quick and easy to remove for service, etc.

I know you want to take no chances, but...do some research on this. It will work.

Just to clarify, I realize that those fragile plastic monsters need full bottom support. All I meant was that you can use a solid top made of perhaps a couple of stacked pieces of plywood to provide that. You can even have a cross-shaped brace underneath, formed from pieces of 2x4 or even 2x6 attached vertically to the bottom of the lowest sheet in the stack. They would run front to back and side to side, sitting between the columns of concrete at each corner. A construction like that absolutely will not allow any flexing, and that's all that "full support" means.

You could even have the columns set 1.5 or 2 inches inside the perimeter of the top, and then run a another vertical brace all around the outside edge, wrapping around the top of the concrete blocks. This would make it simple to attach curtains (fabric or solid) to the bottom of those braces to hide the structure, but which will still be quick and easy to remove for service, etc.

I know you want to take no chances, but...do some research on this. It will work.

wednesday13

Backfromthedead

Fishman Dave M M1A1

Since the project completion is several weeks away I'm reviewing all options. In a perfect world I'd like a woodworker make me a basic stand but seems like everyone wants to build furniture type stands. There is a company I plan to contact.

One thing I've learnt from this thread, and many others started by

FINWIN

, is that if I'm ever planning a complex multi million pound bank raid, then she is by far and away the best person to plan it for me, lol.

FINWIN

, is that if I'm ever planning a complex multi million pound bank raid, then she is by far and away the best person to plan it for me, lol.

She doesn't leave a stone unturned in her approach to anything

She doesn't leave a stone unturned in her approach to anything

Thanks. For the first time in months I'm getting my groove back in fishkeeping. Was pretty much going through the motions from all the losses but now I'm excited about the upcoming tank and new fishy friends! Because of home expenses I'm probably looking at November. East coast prices for everything are ludicrous. NOBODY WANTS TO BUILD A BASIC STAND. Everything has to be big bulky cabinet stuff they can charge you 2 grand for. One more company to try. So I'll be cheap where I can and spend money where I must.

Sometimes my mind races 100 miles an hour when I'm working through ideas. I even have a new list of names, ha haa. The pineapple plants arrived today. The 'green fern' plant looks nothing like the picture....solid deep green blades with white tips. Who comes up with this stuff? Back to Krylon.

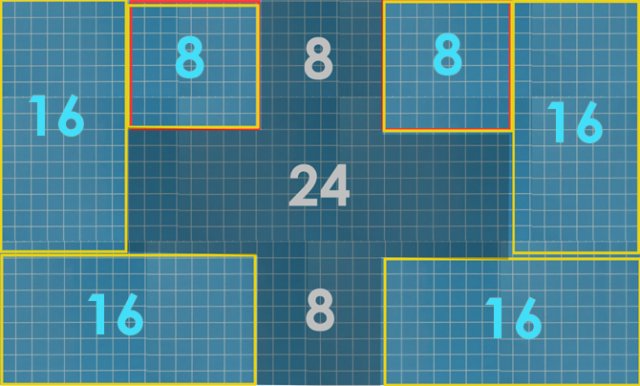

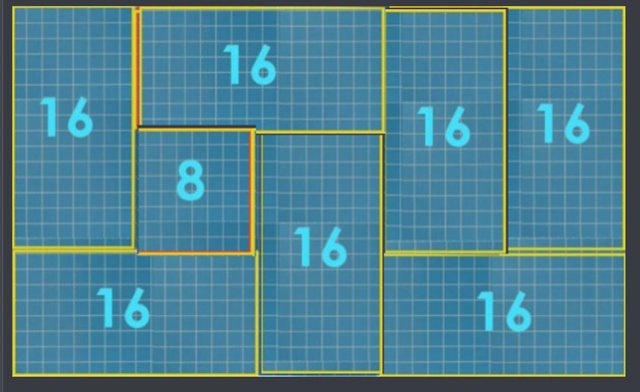

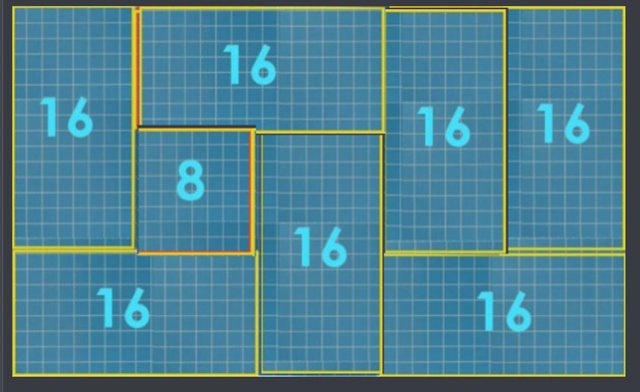

Because I'm not hearing what I like price wise regarding tank stands I'll revise the block layout to SCALE this time. I admit I may have overreacted to the gap space. I might borrow P phreeflow idea of using some 8 inch blocks. I'm reconsidering the layout because of how the 125 is fully supported. It's on a built in tabletop stand and stacked with 3/4" maple on top of that I added. Underneath there's a support frame running the whole perimeter. The bottom is completely open ( I can open the cabinet doors, go underneath and run my hands over the whole tabletop bottom). So this supports jjohnwm

saying all those blocks aren't needed. I'll be drafting a rescaled graphic.

jjohnwm

saying all those blocks aren't needed. I'll be drafting a rescaled graphic.

Anything to keep him from whining about too many blocks...

Sometimes my mind races 100 miles an hour when I'm working through ideas. I even have a new list of names, ha haa. The pineapple plants arrived today. The 'green fern' plant looks nothing like the picture....solid deep green blades with white tips. Who comes up with this stuff? Back to Krylon.

Because I'm not hearing what I like price wise regarding tank stands I'll revise the block layout to SCALE this time. I admit I may have overreacted to the gap space. I might borrow P phreeflow idea of using some 8 inch blocks. I'm reconsidering the layout because of how the 125 is fully supported. It's on a built in tabletop stand and stacked with 3/4" maple on top of that I added. Underneath there's a support frame running the whole perimeter. The bottom is completely open ( I can open the cabinet doors, go underneath and run my hands over the whole tabletop bottom). So this supports

Anything to keep him from whining about too many blocks...

I’m with you

I had major water damage before so i might be a bit paranoid

Thankfully, many of the members have better insight

Almost wish I had enough room to stack some standard metal stands together with a table top. I don't get it...I guess its about money and ego with these buisnesses. You ask for a wood frame stand, they offer a full blown cabinet piece. Maybe a carpenter ? I dunno.

Guess I can't go wrong with this, lol...I ain't spending 2 grand on a stand!

Guess I can't go wrong with this, lol...I ain't spending 2 grand on a stand!

Last edited: