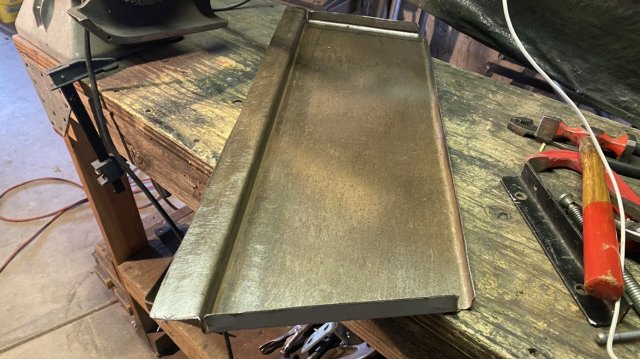

After I welded in these rails for the battery box I discovered the frame had a lot of weld draw that was sucking in the rails.

I did cut those battery box rails and the frame did spring apart but only about 3/16” and I was expecting it to spread over 3/8”.

Well at this point it is what it is and that’s where it’s going to stay. Meanwhile I had to get the rear brake line out of my way so I mocked up the master cylinder and bent the brake line to fit. I cut the fuel line. It will have a filter right below there.

Since the laws in California have changed, finding the racing fuel tank of my dreams at Amazon is hopeless. They won’t deliver it to California.

Anyhow I did find some fuel tanks that they would deliver but not in the shape that I need. I was hoping to get a dragster style tank in this size and shape: A 5 gallon cylinder. This harbor freight tank is a pressure tank and it is very heavy by comparison. Here you can see the two rails I welded in to support the batteries, and if you look closely you can see I cut them in the middle.

I did get the pedal assembly mostly cleaned up, and mounted with cables, spring, etc. Everything clears and operates smoothly enough.

But the arrow in my pic shows where I stuffed a shim in the pedal stop to make things line up.

I need to made some real pedal stops.

Also the brake pushrod needs to be 2 inches longer.

I did cut those battery box rails and the frame did spring apart but only about 3/16” and I was expecting it to spread over 3/8”.

Well at this point it is what it is and that’s where it’s going to stay. Meanwhile I had to get the rear brake line out of my way so I mocked up the master cylinder and bent the brake line to fit. I cut the fuel line. It will have a filter right below there.

Since the laws in California have changed, finding the racing fuel tank of my dreams at Amazon is hopeless. They won’t deliver it to California.

Anyhow I did find some fuel tanks that they would deliver but not in the shape that I need. I was hoping to get a dragster style tank in this size and shape: A 5 gallon cylinder. This harbor freight tank is a pressure tank and it is very heavy by comparison. Here you can see the two rails I welded in to support the batteries, and if you look closely you can see I cut them in the middle.

I did get the pedal assembly mostly cleaned up, and mounted with cables, spring, etc. Everything clears and operates smoothly enough.

But the arrow in my pic shows where I stuffed a shim in the pedal stop to make things line up.

I need to made some real pedal stops.

Also the brake pushrod needs to be 2 inches longer.