Hey everyone, glad to be here and thanks for having me!

I apologize for the length of the post but feel the backstory is important.

Back story - Acquired a 170-gallon rimless tank from a friend the tank is 1/2'' glass at 72'' x 18'' x 30'' I know that's a tall tank to only be 1/2" glass but, overall everything seemed to be in good shape. Some of the bracing at the top was sub par. Definitely a mixture of different owners gluing in different pieces of glass over the years for whatever reasons. The guy I got the tank from is a friend and I had seen the tank full of water and fish multiple times with no issues so I wasn't worried about it.

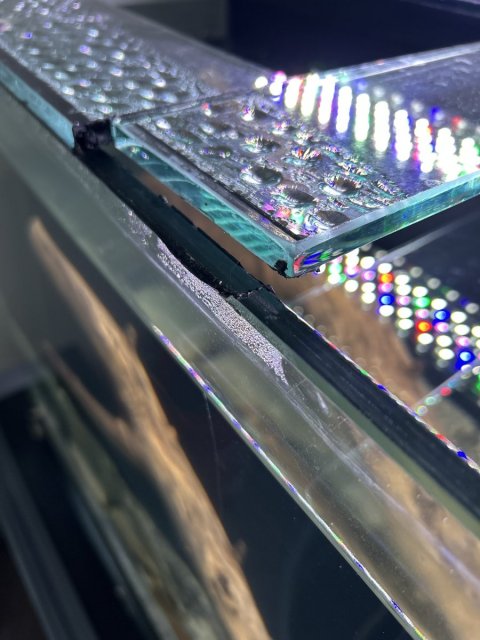

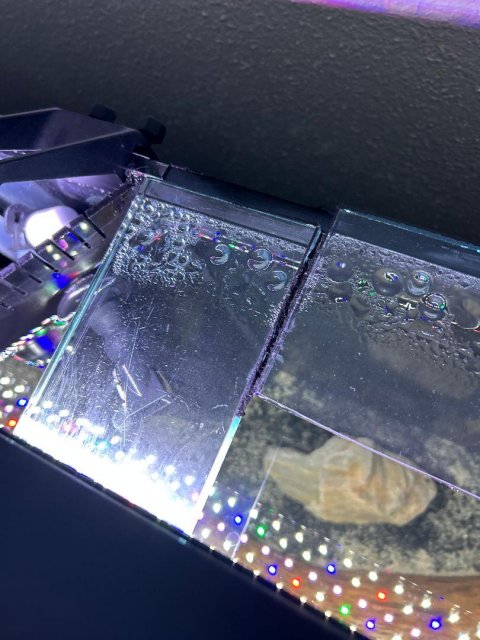

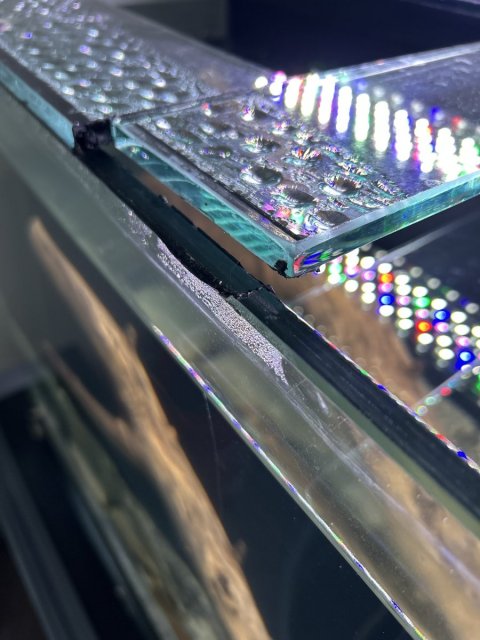

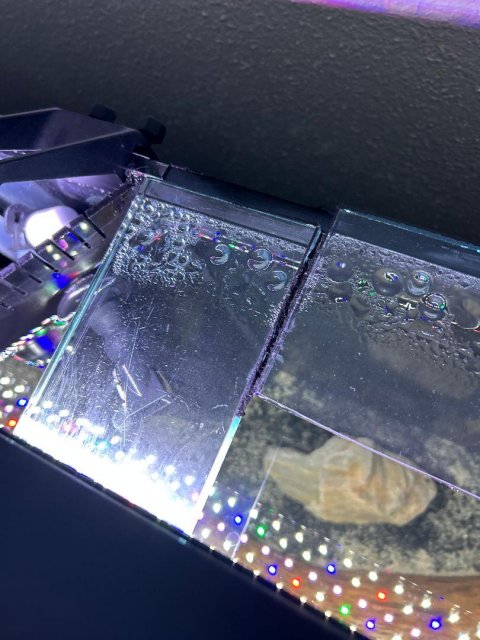

The plan was to give the tank a face lift which included new glass bracing at the top of the tank. A traditional style euro-brace was out of the question as it would limit access to the plumbing behind the weir. So I came up with some top mounted 3/8 glass that framed each side but left the middle of the tank open (see picture 1&2) which would later prove to be a big mistake. Fast forward and we were ready for water.

The tank was full of water for a little over 24 hours when I heard the most terrifying sound come from the fish room. A huge thud! Upon further inspection I saw that the silicone holding the center glass braces running from the front to back panels had let go moving over a 1/2 inch (pictures 2 and 3). Amazing that glass didn't give with that much movement like that. After changing my shorts to a non soiled pair I began to drain water and that brings us to where we are now. How to go about fixing the issue?

1. The strips of glass that let go were only 4 inches wide. Very minimal surface area for the silicone to grab onto.

2. Working with shear strength instead of tensile strength.

3. Open area in the middle with no bracing prone to flexing.

New plan - Going to ditch the Kraken brand silicone and go with Momentive RTV108 much higher tensile and shear rating. Widen the glass strips from 4 inch to 10 inch, yes it will limit access to the weir but wont block it completely. More surface area, more silicone, more holding power. This will also close the gap in the center to about 8 inches. Can also consider adding glass to the inside to add tensile strength and close that seam so to speak

Rtv108

tensile 400psi

shear 200psi

10''x.5 = 5 sq in

5 sq in x 200 = 1000 lbs of holding power without factoring anything else in. Substantial gain over the original which came in around 200 lbs

Does this make sense or am I way over thinking things?

Open to all suggestions!

I've got way too much time and effort into this build, defeat is not an option!

I apologize for the length of the post but feel the backstory is important.

Back story - Acquired a 170-gallon rimless tank from a friend the tank is 1/2'' glass at 72'' x 18'' x 30'' I know that's a tall tank to only be 1/2" glass but, overall everything seemed to be in good shape. Some of the bracing at the top was sub par. Definitely a mixture of different owners gluing in different pieces of glass over the years for whatever reasons. The guy I got the tank from is a friend and I had seen the tank full of water and fish multiple times with no issues so I wasn't worried about it.

The plan was to give the tank a face lift which included new glass bracing at the top of the tank. A traditional style euro-brace was out of the question as it would limit access to the plumbing behind the weir. So I came up with some top mounted 3/8 glass that framed each side but left the middle of the tank open (see picture 1&2) which would later prove to be a big mistake. Fast forward and we were ready for water.

The tank was full of water for a little over 24 hours when I heard the most terrifying sound come from the fish room. A huge thud! Upon further inspection I saw that the silicone holding the center glass braces running from the front to back panels had let go moving over a 1/2 inch (pictures 2 and 3). Amazing that glass didn't give with that much movement like that. After changing my shorts to a non soiled pair I began to drain water and that brings us to where we are now. How to go about fixing the issue?

1. The strips of glass that let go were only 4 inches wide. Very minimal surface area for the silicone to grab onto.

2. Working with shear strength instead of tensile strength.

3. Open area in the middle with no bracing prone to flexing.

New plan - Going to ditch the Kraken brand silicone and go with Momentive RTV108 much higher tensile and shear rating. Widen the glass strips from 4 inch to 10 inch, yes it will limit access to the weir but wont block it completely. More surface area, more silicone, more holding power. This will also close the gap in the center to about 8 inches. Can also consider adding glass to the inside to add tensile strength and close that seam so to speak

Rtv108

tensile 400psi

shear 200psi

10''x.5 = 5 sq in

5 sq in x 200 = 1000 lbs of holding power without factoring anything else in. Substantial gain over the original which came in around 200 lbs

Does this make sense or am I way over thinking things?

Open to all suggestions!

I've got way too much time and effort into this build, defeat is not an option!