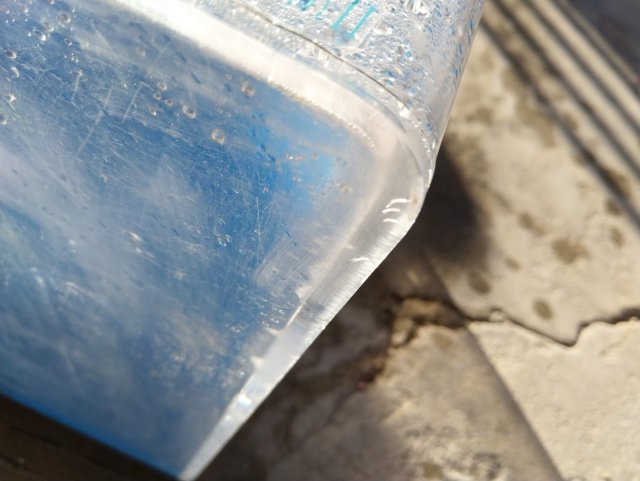

Thanks for the reply Hari. That seam to the right is the one I'm talking about. It's a bead of #40 that I did. It recently started turning while along the sides.it should be clear for a perfect weld like towards the bottom of the seam in your picture, there is higher chance you will have a leak sooner or later, you can try pouring #40 on the inner seams which should take care of any leaks.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Weld-on #40 and #42

- Thread starter wednesday13

- Start date

@Bigofishys ,I have a spots that look like that. that's what the Weldon is for. If you didn't have the Weldon adding reinforcement and sealing you'd be at potential risk.

you will be fine as theres no way water can come between the Weldon and the original acrylic panel. feel free to tag me ? anytime.

Thanks brother. I thought the weld on bead was turning white from stress. My concrete subfloor is uneven and I had to shim the stand quite a bit.@Bigofishys ,I have a spots that look like that. that's what the Weldon is for. If you didn't have the Weldon adding reinforcement and sealing you'd be at potential risk.

you will be fine as theres no way water can come between the Weldon and the original acrylic panel. feel free to tag me ? anytime.

from what I've read its because of the thermal reaction of the Weldon setting up. also the reason you will notice any stress cracks in the original acrylic around where the Weldon is. I too have a concrete floor that's not entirely even. my 8' span is as level as I could get it but in reality most tanks once they've settled aren't truly level.

Thanks for the reply Hari. That seam to the right is the one I'm talking about. It's a bead of #40 that I did. It recently started turning while along the sides.

I see it now, got confused with the reflection, i did my 300g few months ago, i don't see any discoloration yet but as @BichirKing suggested it should be fine. i went crazy with weld-on as i had a gallon kit which was expiring so all my beads were atleast 1 inch.

In regards to the floor, i have similar issue concrete slabs underneath and leaning arond a inch on one end, i didn't like the angled shims so went with 1 inch treated wood running across the depth of the tank and made some thinner ones for the entine width of the tank, got a

7 foot stabila level and got everything figured out, still not happy so got a digital level, now i am 1mm off on one of the side which i don't think its all set now.

better tear it down and do it right or its gonna explodenow i am 1mm off

It’s 300 gallons.Hello! This thread is very helpful!! How many pints of 40 would I need to do all 8 corners of a tank with the dimensions below? The tank is about 20 years old and hasn’t been used in about 6 years.

L 8’

W 24”

H 24”

1/2” acrylic

Maybe @wednesday13 will see the last few posts and help.