^^^^^^Update to the above post^^^^^^

I am probably the rookie out of the group but here's my thought on your situation....

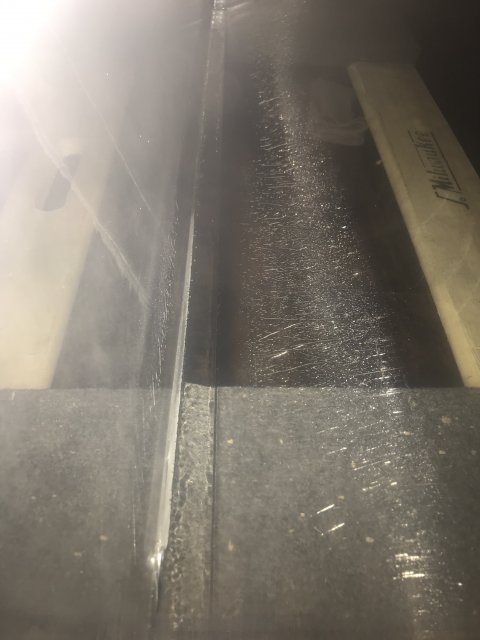

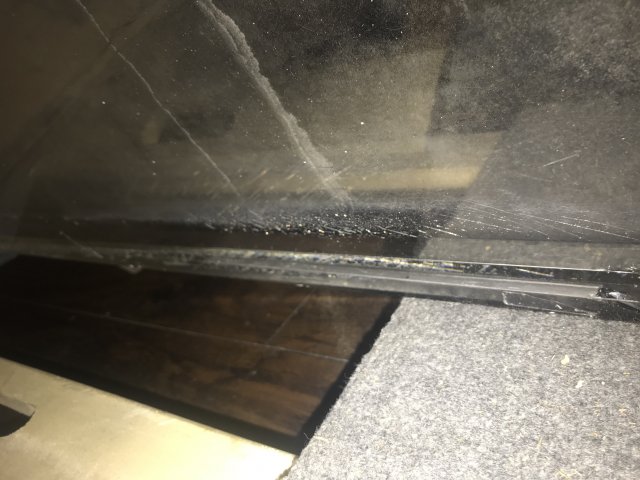

A pint of WO40 is way more Weldon than you need for this job. I would pour because the final product, if done right, will be seamless, clear, and get absorbed and become a part of the 2 acrylic panels. The smell is going to be pretty strong so a respirator is definitely needed. Pour and mix the Weldon in a clear plastic container (we used a paint mixing cup). Mix slow to minimize trapping bubbles. Pinch the lip of that container to create a V shape and pour thru the V. Pour from corner to corner slow enough so that you're actually chasing the Weldon thats running from corner to corner.

The rod you have is extruded acrylic and wont be as clear. Not sure if that will absorb into the acrylic panel when glued in place.

200ml will be enough for that seam. You may have to sand a bit if you get too many bubbles when mixing and pouring. Do some test pours on a junk tank if you have one.

I am probably the rookie out of the group but here's my thought on your situation....

A pint of WO40 is way more Weldon than you need for this job. I would pour because the final product, if done right, will be seamless, clear, and get absorbed and become a part of the 2 acrylic panels. The smell is going to be pretty strong so a respirator is definitely needed. Pour and mix the Weldon in a clear plastic container (we used a paint mixing cup). Mix slow to minimize trapping bubbles. Pinch the lip of that container to create a V shape and pour thru the V. Pour from corner to corner slow enough so that you're actually chasing the Weldon thats running from corner to corner.

The rod you have is extruded acrylic and wont be as clear. Not sure if that will absorb into the acrylic panel when glued in place.

200ml will be enough for that seam. You may have to sand a bit if you get too many bubbles when mixing and pouring. Do some test pours on a junk tank if you have one.