So did you camera break as well??!! Lol

Glad to hear you are actually back at it. I can get excited again.

Haha! Nooo, it did not break!

This has been a wild ride for the last 6 months. Motorcycle wreck, surgery, bolted back together, flights to the L48 and all while trying to keep my professional obligations flying straight has been a trick. Sometimes too much of a trick.

For example, I thought I'd have pics on my camera of having masked and applied the SCS1200 then I remembered...

I did that after a long day's work and didn't even change out of my work clothes as the night was getting late and I had a flight stateside the next day. I hopped in the tank and went for it. I'd never used a quick curing adhesive caulk before and long story short, a white shirt and black pants were donated to the gods that evening. SCS1200 does not lend itself to an immaculate application and instead gets on a lot of stuff you weren't expecting even if you've done a fair bit of silicone work in the past. To overshare for just a second note that 40' of bead does not go on instantaneously and during my installation I rec'd a call from nature that became more pressing with every foot of bead applied. As soon as I knocked out the tank I noticed that my pants and shirt were done for and some of that stuff was on my hands... but nature is a poor negotiator. I jumped out of the tank, ran upstairs and smeared adhesive silicone on the door knob to the bathroom as I slid to a stop before the oracle.

At that point a very real conundrum became apparent, the details of which I will spare you. That kind of caulk does get everywhere though.

So no pics of the masking and prep work.

Backfromthedead

Backfromthedead

asked about how well I cleaned the seams. I cleaned them like an electrical engineer with OCD. All surfaces razor shaved, anything left was hit w/ a heat gun and shaved again then any possible residue was removed w/ acetone. When the acetone had dried I cleaned the glass once more, this time w/ H

2O

2 and then all trim lines were masked.

My bead was irregular in part because I had never used a battery powered caulking gun before that night. It was also true that I'd never applied an adhesive caulk and had I known how different it is I'd have blown a tube for practice. SCS1200 sets extremely quickly. Too quickly for a 40' bead of caulk to be applied and then shaped. Even just pulling the masking away presented new and unexpected problems. I thought I'd apply this to look like a welder's stacked nickels and instead it turned out looking like something my dog might leave in the yard.

When you pull the masking any caulk that had adhered to the tape would be sticky enough that it would pull at the balance of the caulk that was stuck exactly where you wanted it. Didn't much matter though as you're already done and the tape can't stay in the tank.

I pulled.

My nostrils were on fire and the caulk job was looking worse w/ each foot of tape removed but whatever the mistake was; it had already been made.

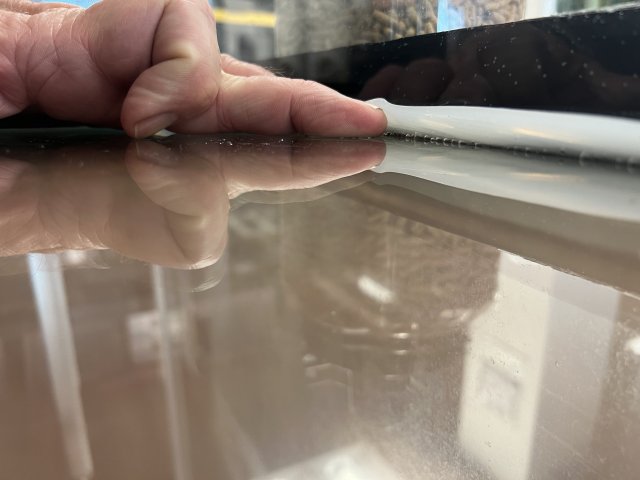

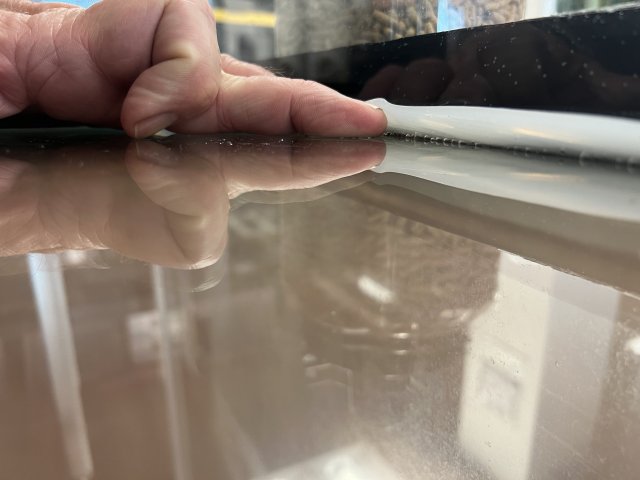

As you look down the length of the bead you can see where removal of the masking had pulled at the bead and made it irregular. It all looked reasonably symmetrical prior to pulling the tape. This was a point where strong language came into play.

What you see here is that the bead pulled away in some places such that it looked like it *might* still work but it was not a sure deal. Not even close.

I'm not a fan of SCS1200 for larger tanks. I'll use up what I've got left for some smaller tanks (I tear down and refurbish old stainless steel framed aquariums when I find them). I think I'll go back to GE Silicone 1 although their 7 year mold free comment on the tube makes me a little scared. I do know how to apply that stuff and know I can have it turn out looking good.

SCS1200 though... I know a couple ways to apply it that don't work well at all.

Yikes! This is not good news. You, sir, have stick-to-it-iveness in spades. When you were "gently" woken up with the news of this latest problem...were any more bones broken during the process?

As a self preservation tool I've opted to go nearly deaf to certain tones. Works great on days like that.

I may try that maskless idea, too. I've got one of the little shaping tools but usually just use a finger dipped in water or sometimes rubbing alcohol if it's around a sink, etc.. Not on this stuff though!