The builder should have just cut this all away to begin with.

Instead of making this big access hole and then closing it.

BUT perhaps the various repairs were done at different times. The welding does not all look like the same guy did it.

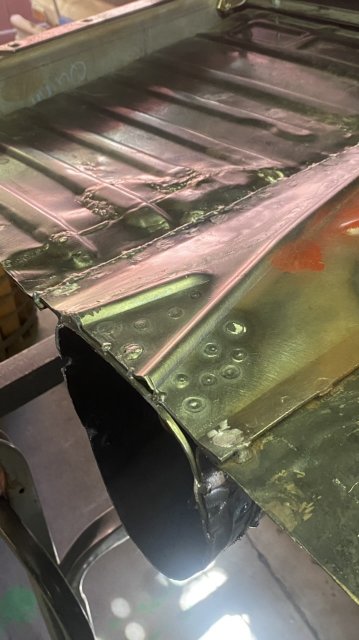

That big hole had been poorly MIG welded. I went over it all with a grinder and wire brush, then TIG welded over it from both sides.

I ended up cutting off things I had already welded on, because of hidden rust.

Now I am making the various patches (4) I need to weld on, before I square this all up and do the real welding.

This old piece from my dad’s lawn tractor has a nice flange already bent on it. It is much stronger than the original metal and twice as thick as the crappy patch which was on there.

Instead of making this big access hole and then closing it.

BUT perhaps the various repairs were done at different times. The welding does not all look like the same guy did it.

That big hole had been poorly MIG welded. I went over it all with a grinder and wire brush, then TIG welded over it from both sides.

I ended up cutting off things I had already welded on, because of hidden rust.

Now I am making the various patches (4) I need to weld on, before I square this all up and do the real welding.

This old piece from my dad’s lawn tractor has a nice flange already bent on it. It is much stronger than the original metal and twice as thick as the crappy patch which was on there.