You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Weld-on #40 and #42

- Thread starter wednesday13

- Start date

I washed it with the hose and used a clean new scubby pad, then wiped it down with acetone before I started.

you shouldnt need that much... 1/2 gal will b more than plenty for those dimensions. it does have a shelf life when opened so its honestly a bit better to order by the pint that way if u dont use it all it wont go bad.

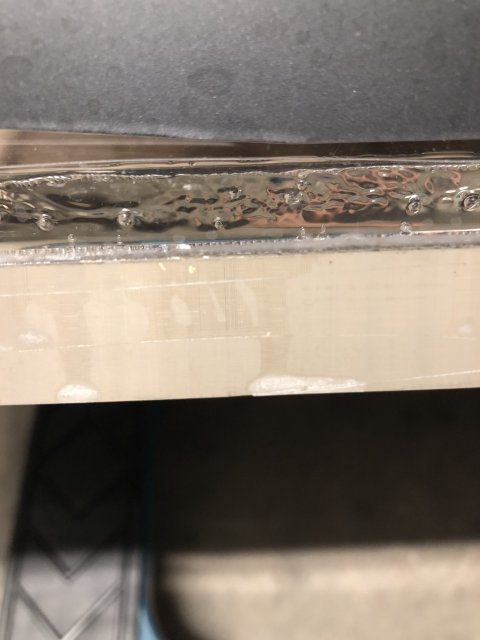

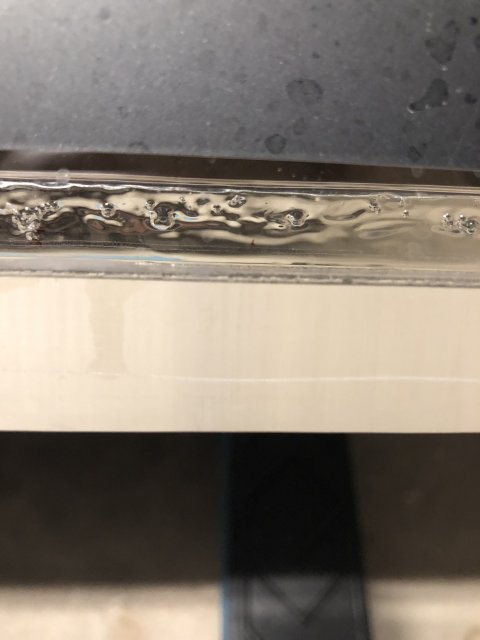

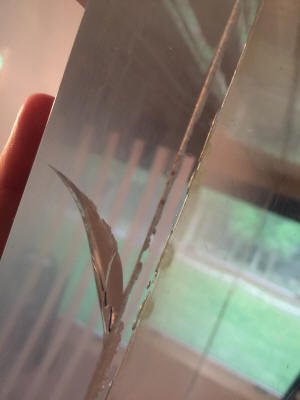

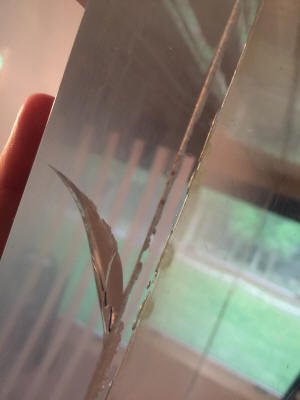

Finally am doing my pours. Did the back first and now the front. Can you guys look at the pics and tell me that the pours look normal. I thought it would be more like glass but it does not look that way, it looks wavy or gelatinous when it dried. I’m questioning the adhesion.. 1st 3 pics are from the outside and the last one is from the inside. Also I went around the outside with the needle and # 4you shouldnt need that much... 1/2 gal will b more than plenty for those dimensions. it does have a shelf life when opened so its honestly a bit better to order by the pint that way if u dont use it all it wont go bad.

looks good/normal to me...nice job man! it always dries just like that so no worries there. ur pours/bevels look thick enough also.Finally am doing my pours. Did the back first and now the front. Can you guys look at the pics and tell me that the pours look normal. I thought it would be more like glass but it does not look that way, it looks wavy or gelatinous when it dried. I’m questioning the adhesion.. 1st 3 pics are from the outside and the last one is from the inside. Also I went around the outside with the needle and # 4

View attachment 1371549

View attachment 1371550

View attachment 1371551

View attachment 1371552

I ALSO POURED A BEVEL ON THE CENTER BRACE. I SEE THESE ALSO COME APART OFTEN ON MANY TANKS SO I FIGURED IT WOULD HELP STRENGTHEN THAT SO I WONT HAVE THAT ISSUE.....THANKS FOR THE KNOWLEDGE YOU HAVE SPILLED OVER THIS FORUM.looks good/normal to me...nice job man! it always dries just like that so no worries there. ur pours/bevels look thick enough also.

if you want a smoother finish the ambient temp in the room and thus the acrylic should be warmer. I learned that it helps get bubbles and waves out. but it looks fine. I watched a guy flame polish his pours right before it set but that seemed like something i could screw up so i didn't. smart on doing the brace too.

A few additional questions guys.Is there any special techniques for applying the WO40? The seam is only 30 inches long. I was thinking of just running the entire bead. I'm also wondering how much I should mix? Even if I waste the entire pint I would save fourfold of what I was quoted for the repair. Lastly is there a benefit to using a rod? I have a 3/4" square rod but if its better to just use the WO to make a reinforcement I'll do that. I found a picture online that looks identical to what I have. @wednesday13 @BichirKing @rocco1100 @Oughtsix

I am probably the rookie out of the group but here's my thought on your situation....

A pint of WO40 is way more Weldon than you need for this job. I would pour because the final product, if done right, will be seamless, clear, and get absorbed and become a part of the 2 acrylic panels.

The rod you have is extruded acrylic and wont be as clear. Not sure if that will absorb into the acrylic panel when glued in place.

200ml will be enough for that seam. You may have to sand a bit if you get too many bubbles when mixing and pouring. Do some test pours on a junk tank if you have one.

A pint of WO40 is way more Weldon than you need for this job. I would pour because the final product, if done right, will be seamless, clear, and get absorbed and become a part of the 2 acrylic panels.

The rod you have is extruded acrylic and wont be as clear. Not sure if that will absorb into the acrylic panel when glued in place.

200ml will be enough for that seam. You may have to sand a bit if you get too many bubbles when mixing and pouring. Do some test pours on a junk tank if you have one.