Im all for it lol… glass bang till the end ??

So as I mentioned yesterday I was going to call the manufacturer.

I sent him an email with all the pics. He said that the panels that they have been getting are not 100% flat and are bowed at times. He said that from looking at the pics it should be no issue, seam separation occurs when there are differences much greater than that.

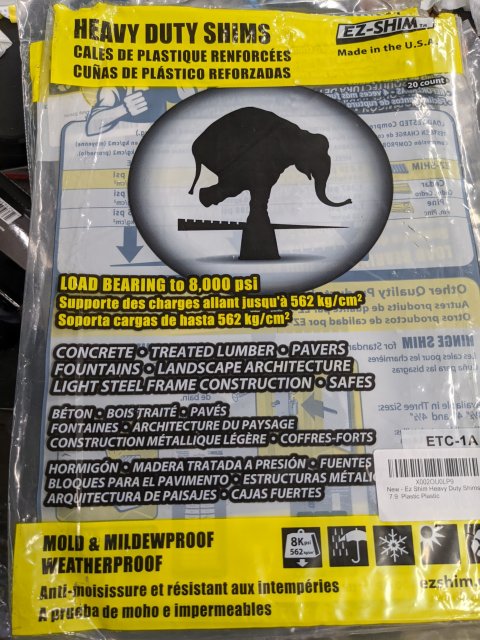

He said that IF you want, you can shim the wood to meet the tank but that's not necessary for this small of a gap.